Rotary Screw Air Compressor Oil

Perfect choice for air solution!

Rotary Screw Air Compressor

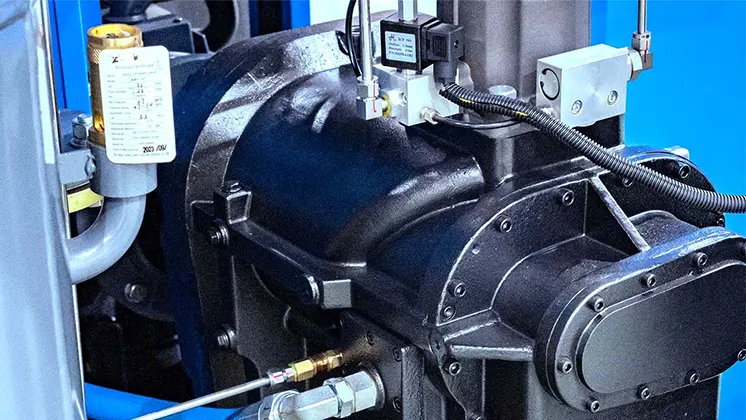

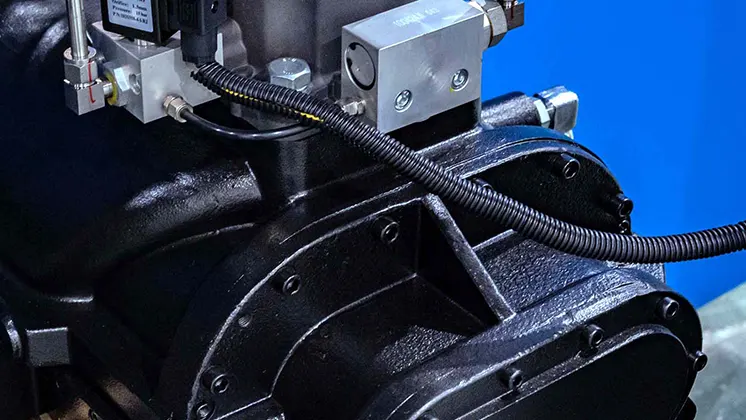

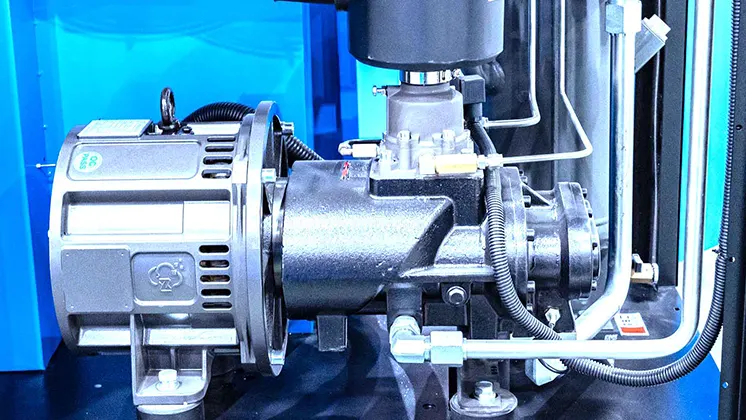

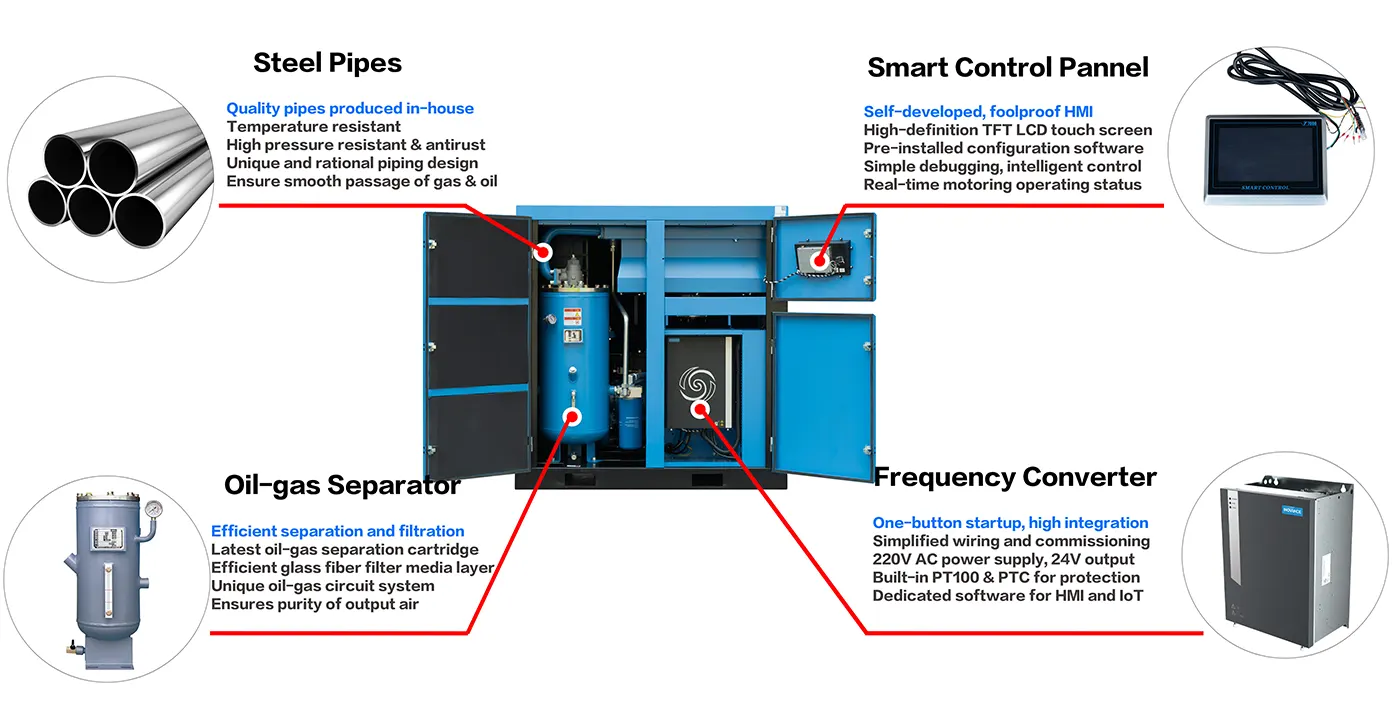

Rotary Screw Air Compressor Oil JX-50APML is developed for the Rotary Screw Air Compressor application to enhance the efficiency, reliability and durability of the equipment. This is high quality oil that improves the compressor efficiency and at the same time sustains long-lasting equipment. Because of its excellent certainty in lubrication, it does not exert pressure and stress on internal components hence suitable for rigorous industrial application.

JX-50APML

- Pressure(MPa): 1.6/2.0

- FAD (m³/min): 3.4/3.2

- Power(KW/HP): 37/50

- Dimension(mm): 1200*1000*1390

- Weigt(kg): 600

- Pipe Diameter: G1 1/2

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

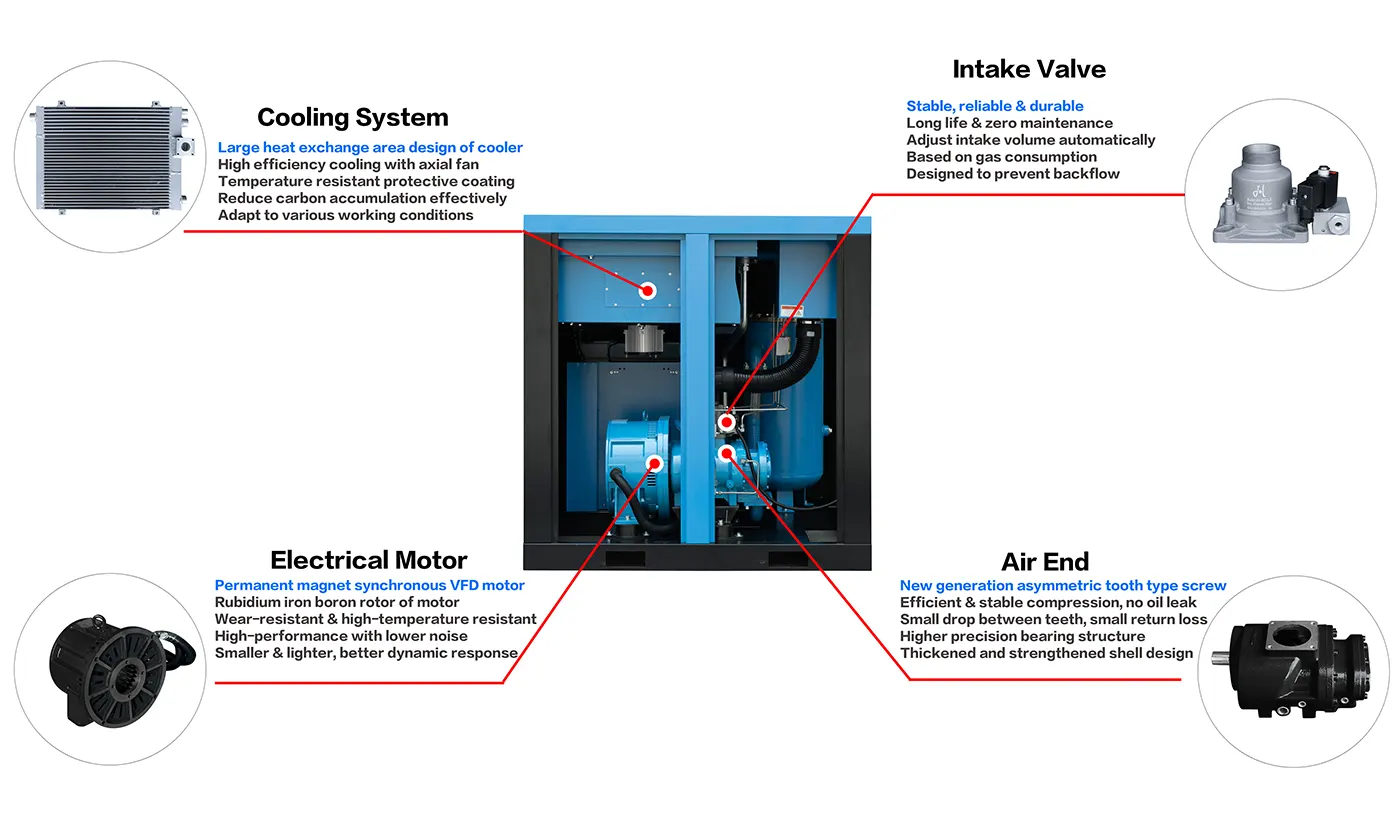

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 800*650*860

-

Weigt(kg): 180

-

Pipe Diameter: G1/2

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-15APML

-

Pressure(MPa): 1.6

-

FAD (m³/min): 0.9

-

Power(KW/HP): 11/15

-

Dimension(mm): 1000*750*1000

-

Weigt(kg): 300

-

Pipe Diameter: G3/4

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-20APML

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 1.2/1.0

-

Power(KW/HP): 15/20

-

Dimension(mm): 1000*750*1000

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APML

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 2.5/2.2

-

Power(KW/HP): 30/40

-

Dimension(mm): 1070*850*1140

-

Weigt(kg): 450

-

Pipe Diameter: G1

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-XG15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch