All In One Air Valve For Compressor

Perfect choice for air solution!

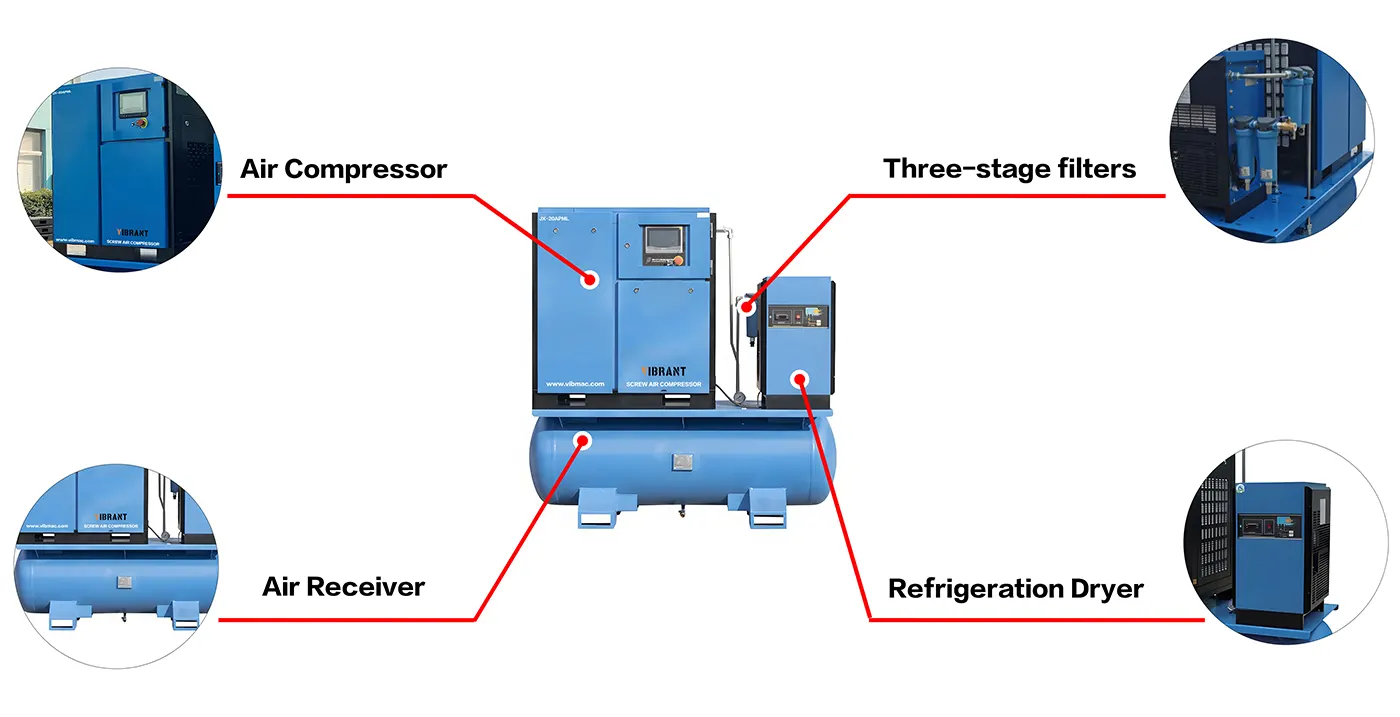

All In One Air Compressor

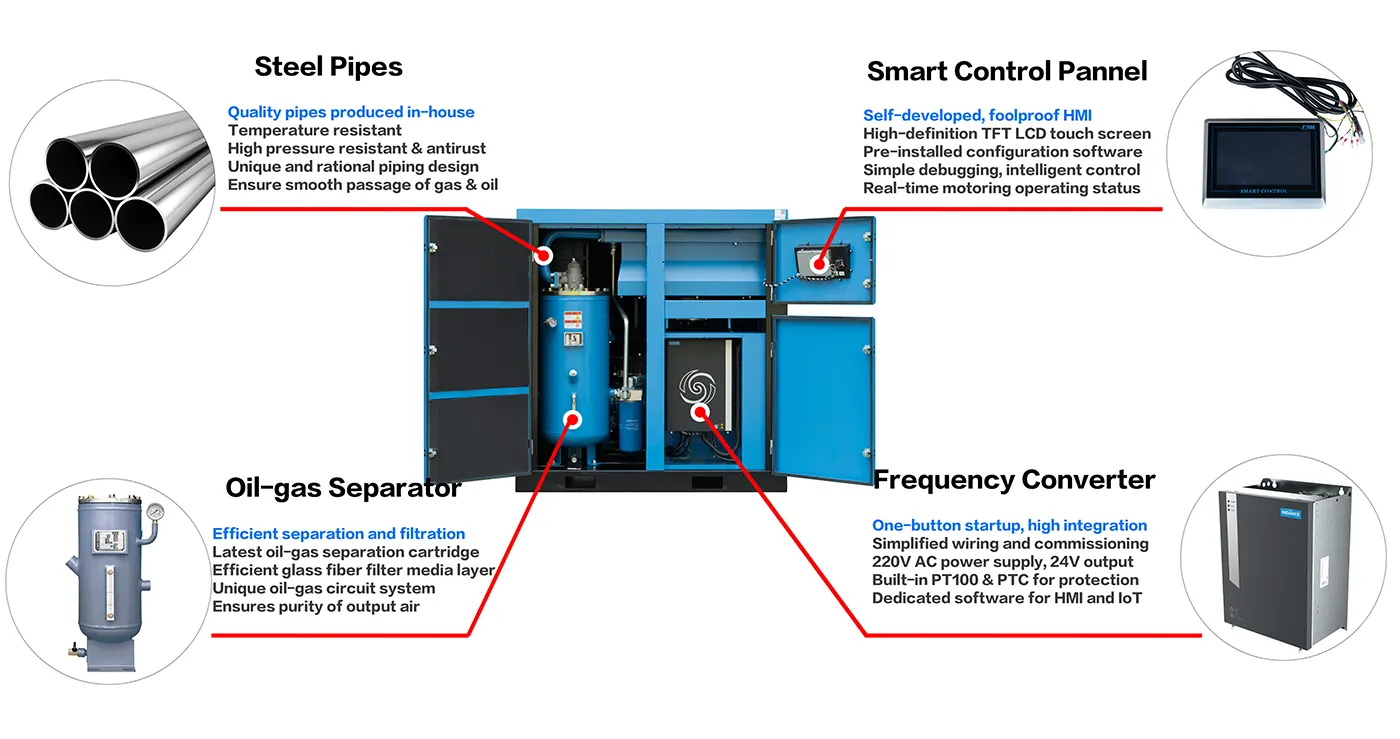

The JX 20APMLT is an air compression equipment and as such, is versatile due to the flexibility that the small size of the equipment brings when using compression air in different sectors. With an integrated air receiver and various performance options, this unit is designed for small workshops and very many industrial uses where reliability and space are vital.

JX-20APMLT

- Pressure(MPa): 1.6/2.0

- FAD (m³/min): 1.2/1.0

- Power(KW/HP): 15/20

- Dimension(mm): 1800*750*1770

- Weigt(kg): 590

- Pipe Diameter: G3/4

- Air Receiver(L): 400

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-10APMLT

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 1500*670*1430

-

Weigt(kg): 355

-

Pipe Diameter: G1/2

-

Air Receiver(L): 220

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-15APMLT

-

Pressure(MPa): 1.6

-

FAD (m³/min): 0.9

-

Power(KW/HP): 11/15

-

Dimension(mm): 1800*750*1770

-

Weigt(kg): 570

-

Pipe Diameter: G3/4

-

Air Receiver(L): 400

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-30APMLT

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 2.0/1.7

-

Power(KW/HP): 22/30

-

Dimension(mm): 1800*850*1930

-

Weigt(kg): 690

-

Pipe Diameter: G1

-

Air Receiver(L): 400

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APMLT

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 2.5/2.2

-

Power(KW/HP): 30/40

-

Dimension(mm): 1800*850*1930

-

Weigt(kg): 720

-

Pipe Diameter: G1

-

Air Receiver(L): 400

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-XG15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch