All In One Air Compressor Generator

Perfect choice for air solution!

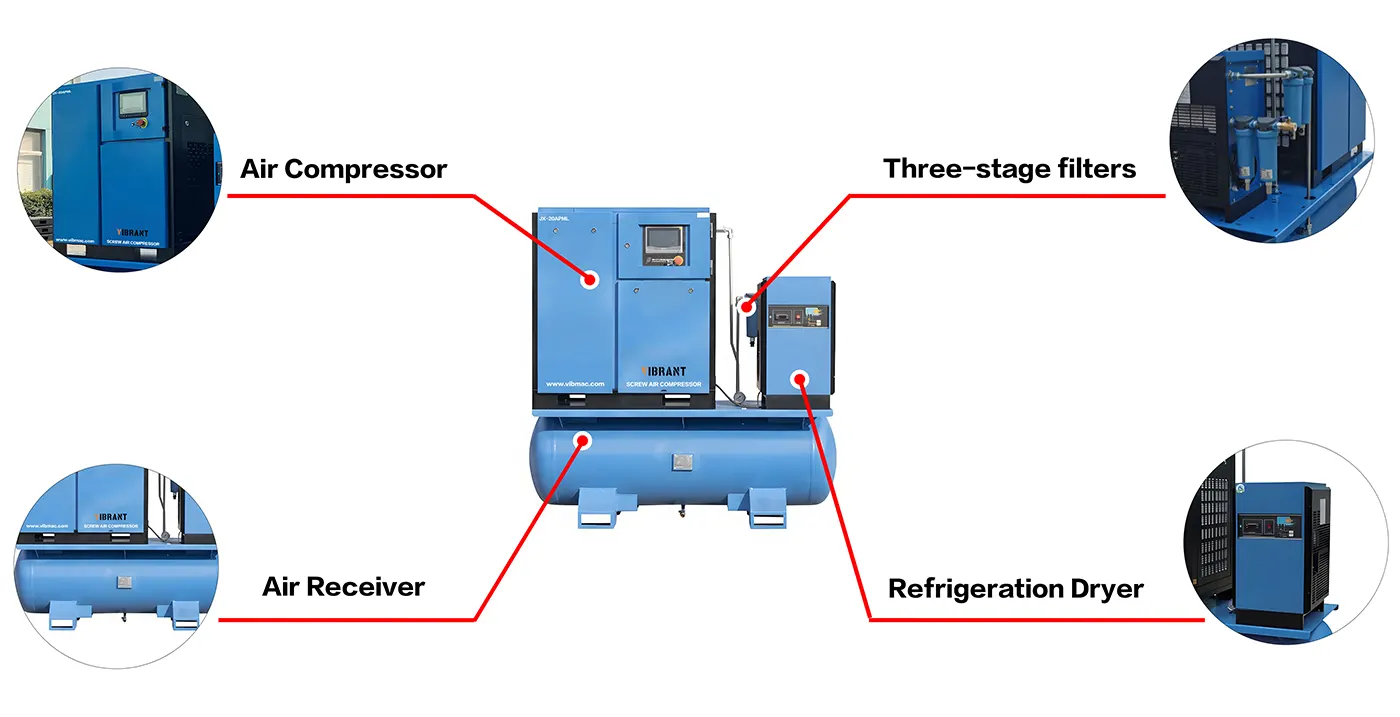

All In One Air Compressor

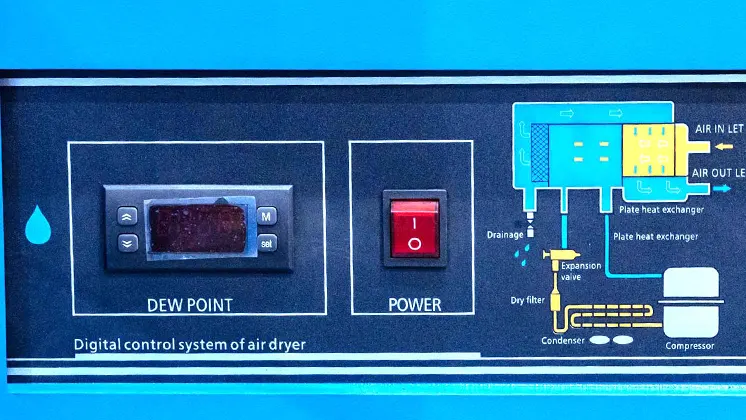

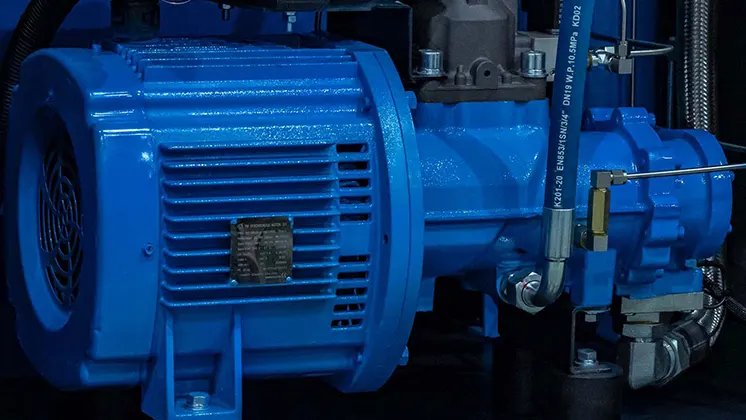

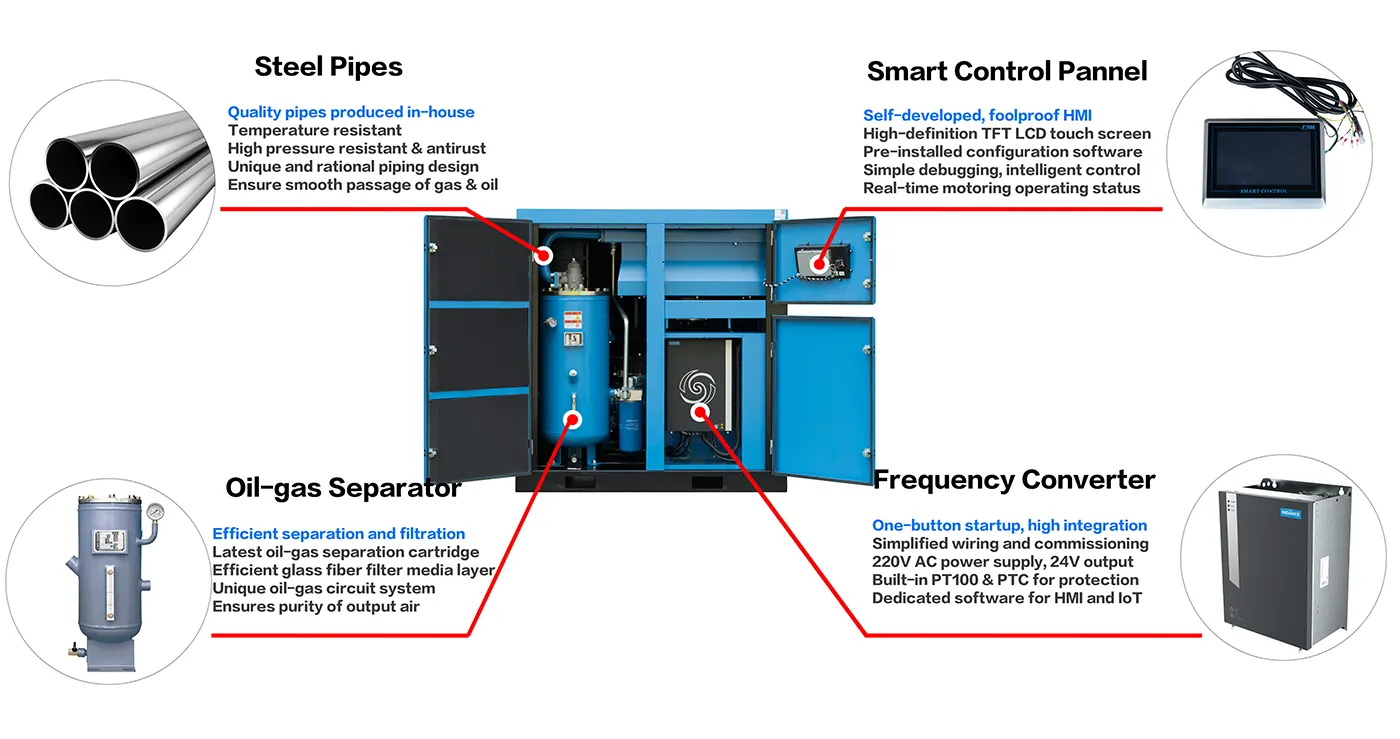

Let me introduce you to the JX-10APMLT All-In-One Air Compressor Generator as appropriate for several purposes. Powered by a 7.5 kW (10 HP) motor, this unit will deliver optimal performance in compressor and energy applications including in carpentry shops and construction sites. It has an air receiver tank of 220 Liters, operates at a pressure of 1.55Mpa, 225psi with a FAD of 0.6 m³ min; 21.2 CFM that suffices the pneumatic tools/equipment sufficiently to enable them to perform optimally.

JX-10APMLT

- Pressure(MPa): 1.55

- FAD (m³/min): 0.6

- Power(KW/HP): 7.5/ 10

- Dimension(mm): 1500*670*1430

- Weigt(kg): 355

- Pipe Diameter: G1/2

- Air Receiver(L): 220

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-15APMLT

-

Pressure(MPa): 1.6

-

FAD (m³/min): 0.9

-

Power(KW/HP): 11/15

-

Dimension(mm): 1800*750*1770

-

Weigt(kg): 570

-

Pipe Diameter: G3/4

-

Air Receiver(L): 400

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-30APMLT

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 2.0/1.7

-

Power(KW/HP): 22/30

-

Dimension(mm): 1800*850*1930

-

Weigt(kg): 690

-

Pipe Diameter: G1

-

Air Receiver(L): 400

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-40APMLT

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 2.5/2.2

-

Power(KW/HP): 30/40

-

Dimension(mm): 1800*850*1930

-

Weigt(kg): 720

-

Pipe Diameter: G1

-

Air Receiver(L): 400

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50APMLT

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 3.4/3.2

-

Power(KW/HP): 37/50

-

Dimension(mm): 1990*980*1970

-

Weigt(kg): 930

-

Pipe Diameter: G1 1/2

-

Air Receiver(L): 300*2

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-XG15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch