Air Compressor Belt Driven

Perfect choice for air solution!

Belt Driven Air Compressor

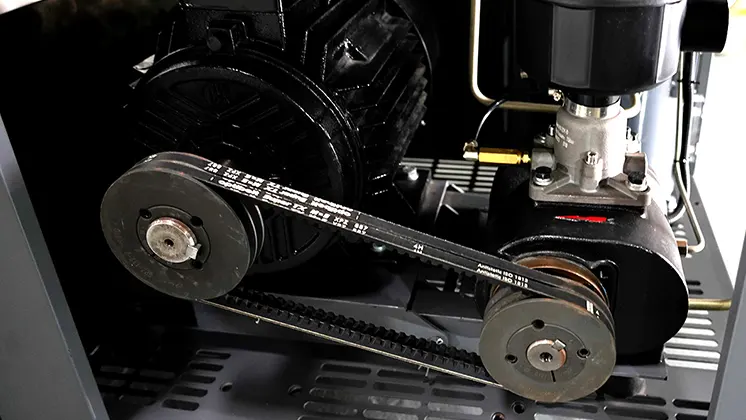

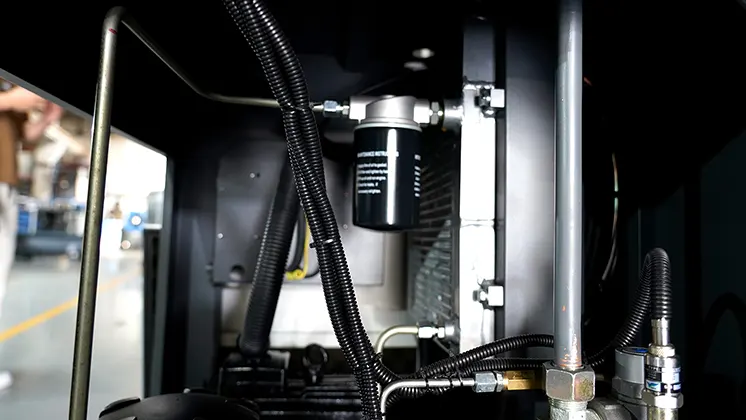

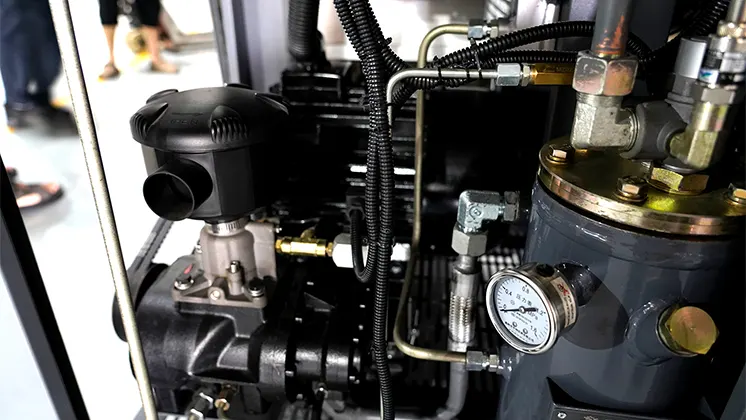

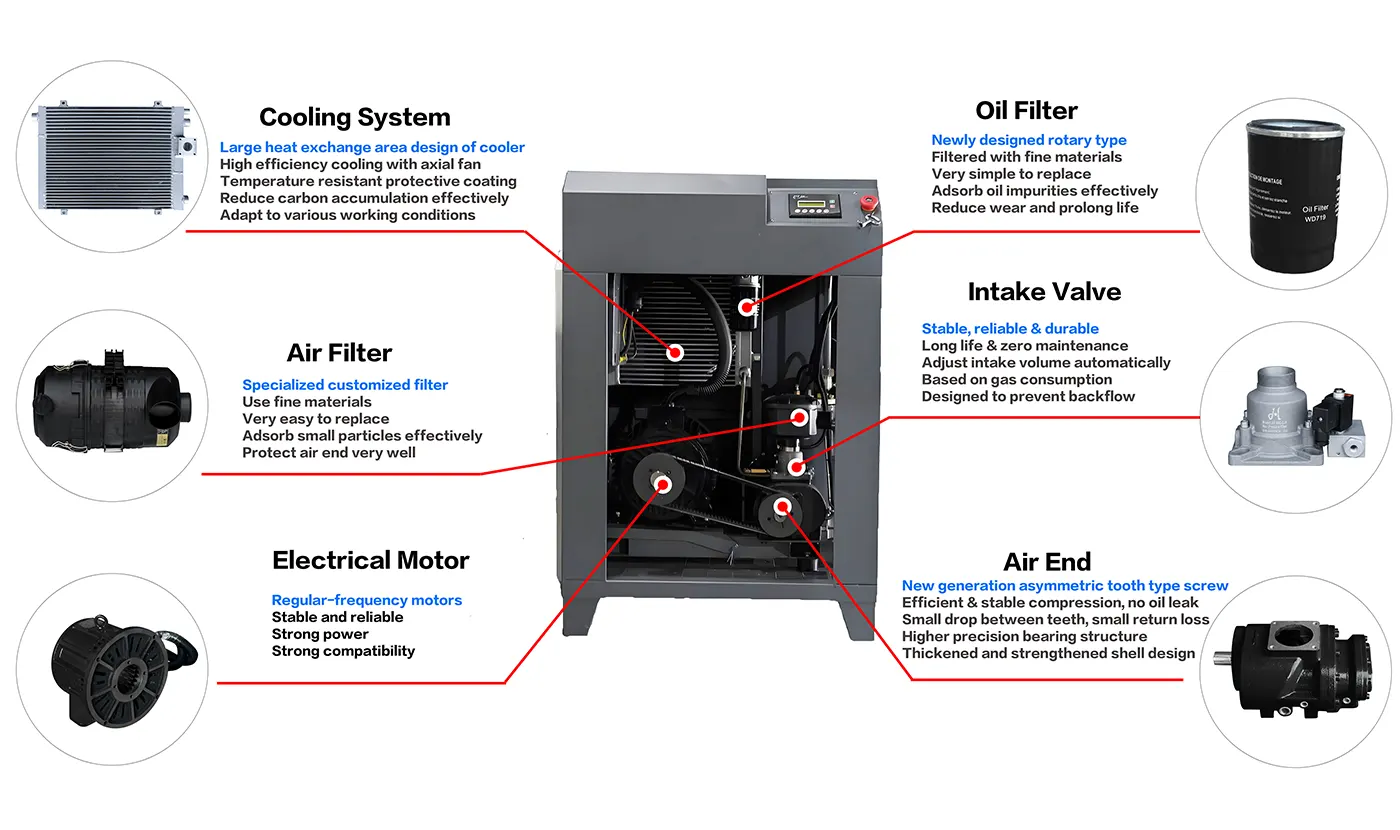

The B-X10A-16 air compressor belt driven comes as the ultimate choice for superior compressed air delivery. If you are operating in a mill environment or confined construction site, this belt-driven compressor guarantees operation effectiveness and easy handling. This product is small in size while at the same time is designed with a robust nature that ensures that it can be easily migrated, installed, and operated in any environment even the most harsh ones. Starting from running small tools to sustaining large pieces of industrial machinery, the B-X10A-16 is designed to keep your business going and give you less troubleshooting time.

B-X10A-16

- Pressure(MPa): 1.6

- Exhaust Volume(m³/min): 0.5

- Power(KW/HP): 7.5/10

- Dimension(mm): 750*700*930

- Drive Mode: Belt

- Weigt(kg): 170

- Pipe Diameter: G1/2

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

B-X10A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.1

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 750*700*930

-

Drive Mode: Belt

-

Weigt(kg): 170

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-X10A-16

-

Pressure(MPa): 1.6

-

Exhaust Volume(m³/min): 0.5

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 750*700*930

-

Drive Mode: Belt

-

Weigt(kg): 170

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

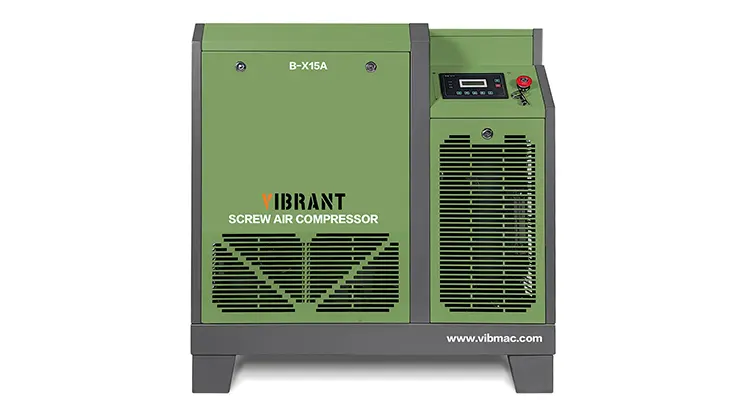

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

-

Dimension(mm): 920*650*960

-

Drive Mode: Belt

-

Weigt(kg): 280

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

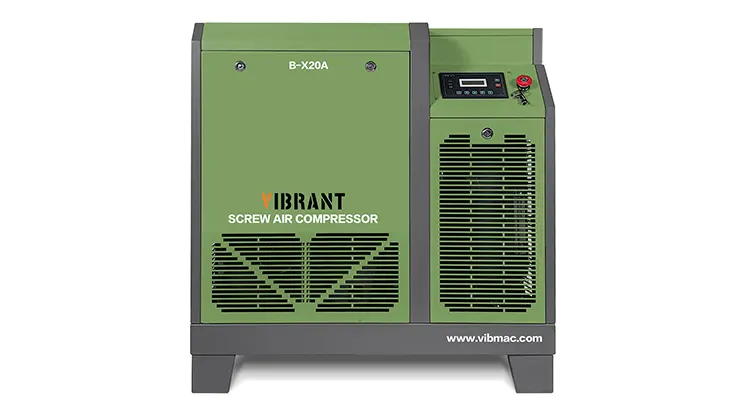

B-X20A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 2.3

-

Power(KW/HP): 15/20

-

Dimension(mm): 920*650*960

-

Drive Mode: Belt

-

Weigt(kg): 300

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-XG15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Get In Touch