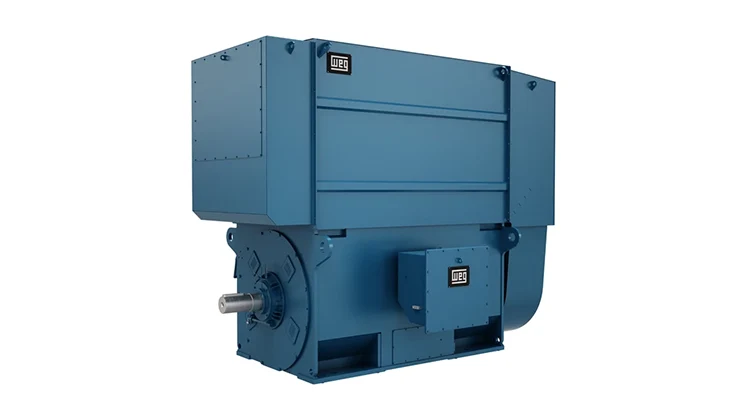

Three-Phase Induction Weg Motor

Compressed air moves with you!

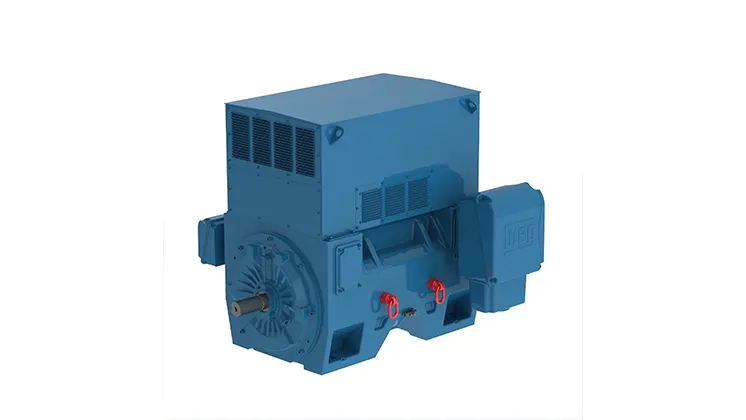

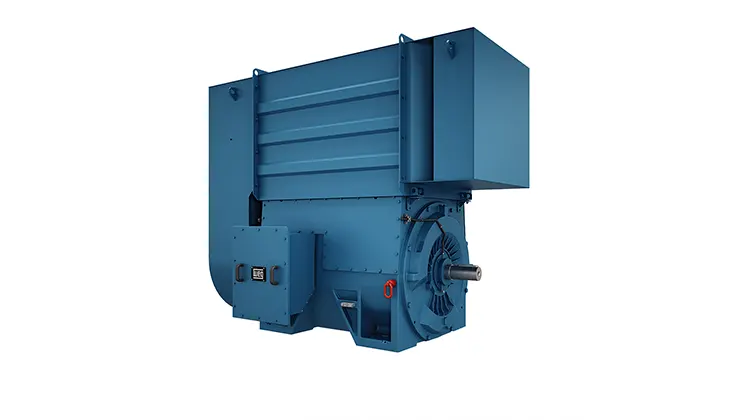

W60 Three-phase Induction WEG Motor

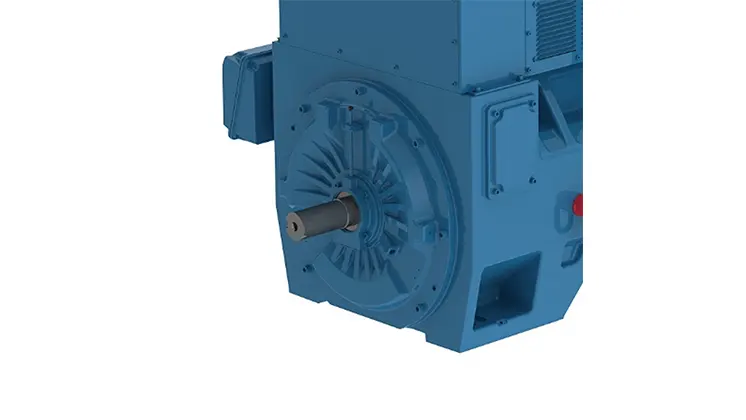

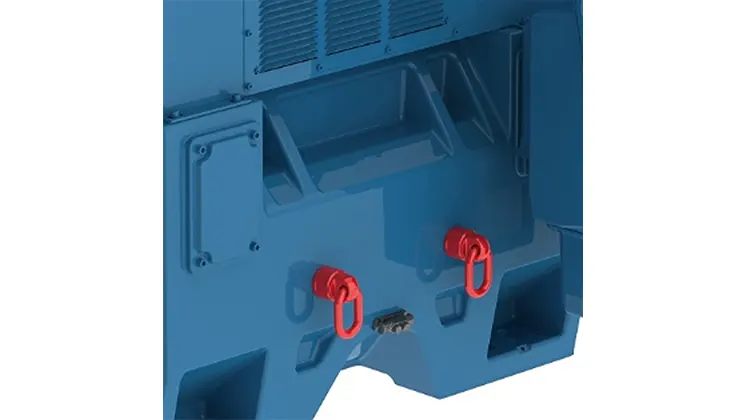

The W60 Three-Phase Induction Motor is a high-output motor that is intended for use in several high-power applications. This motor has a rated output of between 1000 kW and 7500 kW to efficiently address the heaviest operations in various industries. It has a vertical mounting option, which reduces space consumption when mounted but offers great performance. The motor’s cooling system selections include IC01, IC611, and IC81W to allow the motor to run at the correct temperature in all climates. Some of the most important components provided by the new W60 motor include RTD Pt-100 temperature sensors, as well as high IP66 protection for the stator connection box.

W60 Three-phase Induction WEG Motor

- Rated output: 1,000 up to 7,500 kW

- Number of poles: 10 up to 18

- Frequency: 50 Hz/60 Hz

- Frame: 630, 710 and 900

- Voltage: 2,300 up to 13,800 V

- Mounting: vertical

- Service Factor: 1.00

- Cooling Method: IC01, IC611 and IC81W

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

W60 Three-phase Induction WEG Motor

-

Rated output: 1,000 up to 7,500 kW

-

Number of poles: 10 up to 18

-

Frequency: 50 Hz/60 Hz

-

Frame: 630, 710 and 900

-

Voltage: 2,300 up to 13,800 V

-

Mounting: vertical

-

Service Factor: 1.00

-

Cooling Method: IC01, IC611 and IC81W

VIEW MORE

HGF-Three phase Induction Motor

-

Rated Output: 355 kW~2800 kW

-

Number of Poles: 2 ~12

-

Frequency: 50/60 Hz

-

Voltage: 2,300V~6,600 V

-

Service Factor: 1.00

-

Insulation Class: F (DT 80 K)

-

Degree of Protection: IP55

-

Mounting: Vertical or Horizontal

-

Enclosure Material: FC-200 cast iron

-

Cooling Method: TEFC (IC411) – Totally Enclosed Fan Cooled

VIEW MORE

W60 Vertical Line Three

-

Rated output: 1,000 up to 7,500 kW

-

Number of poles: 10 up to 18

-

Frame: 630, 710 and 900

-

Voltage: 2,300 up to 13,800 V

-

Frequency: 50 or 60 Hz

-

Mounting: Vertical

VIEW MORE

MASTER Series Large Induction Motors

-

Output: up to 50,000 kW

-

Frequency: 50 or 60 Hz

-

Voltage: 220 to 13,800 V

-

Frame: 280 to 1800 (IEC)

-

Speed: 3,600 to 300 rpm

-

Rotor: Squirrel cage

-

Insulation Class: F or H

-

Mounting: Horizontal or vertical

-

Bearing: Ball bearing or sleeve bearing

-

Degree of Protection: IP23, IP24(W), IP55, IP56 or IP65

VIEW MORE

You May Also Like

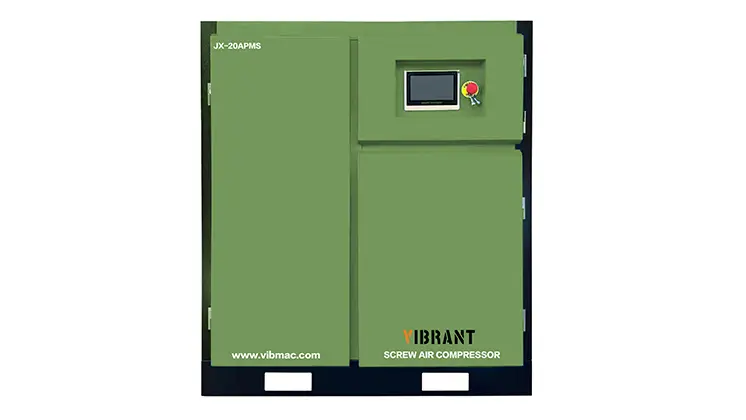

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

JX-15APMX-11KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Z-G10A-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE

Get In Touch