Rotary Screw Portable Air Compressor

The new B-XG15A Rotary Screw Portable Air Compressor provides industrial and site users the power of a stationary air compressor with the flexibility of mobility application. A 15 HP motor and an air receiver of 330L are expected in this compressor to meet modern-day needs. It uses high-quality rotary screw technology for its continuous and consistent airflow besides its compact structure for easy mobility. This air compressor caters to many applications from construction sites where there is a need to power pneumatic tools, to workshops where there is a need to supply compressed air in large quantities The B-XG15A gives a consistent performance and hence is very efficient making it preferable for commercial uses.

- Pressure(MPa): 0.8

- Exhaust Volume(m³/min): 1.5

- Power(KW/HP): 11/15

- Dimension(mm): 1160*660*1660

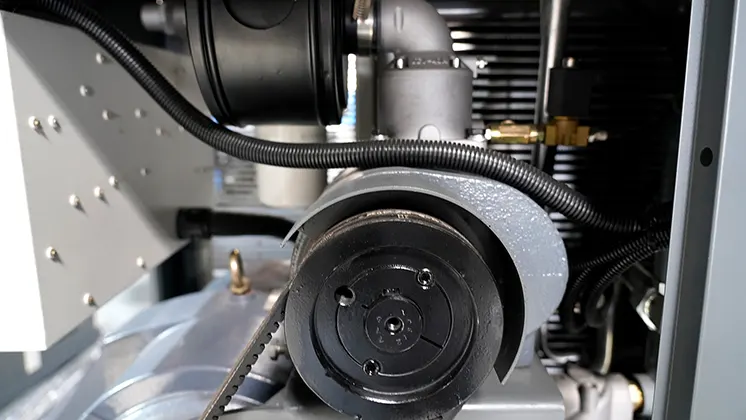

- Drive Mode: Belt

- Weigt(kg): 340

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Gas Tank(L): 330, available for customization

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1500*540*1120

-

Drive Mode: Belt

-

Weigt(kg): 245

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 250, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1550*580*1230

-

Drive Mode: Belt

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 300, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 1.5-1.3

-

Power(KW/HP): 11/15

-

Dimension(mm): 1500*700*1600

-

Drive Mode: Belt

-

Weigt(kg): 510

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 430, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 0.67

-

Power(KW/HP): 5.5/7.5

-

Dimension(mm): 1250*480*1060

-

Drive Mode: Belt

-

Weigt(kg): 190

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 210, Available for Customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE