Small Portable Rotary Screw Air Compressor

Compressed air moves with you!

Portable Rotary Screw Air Compressor

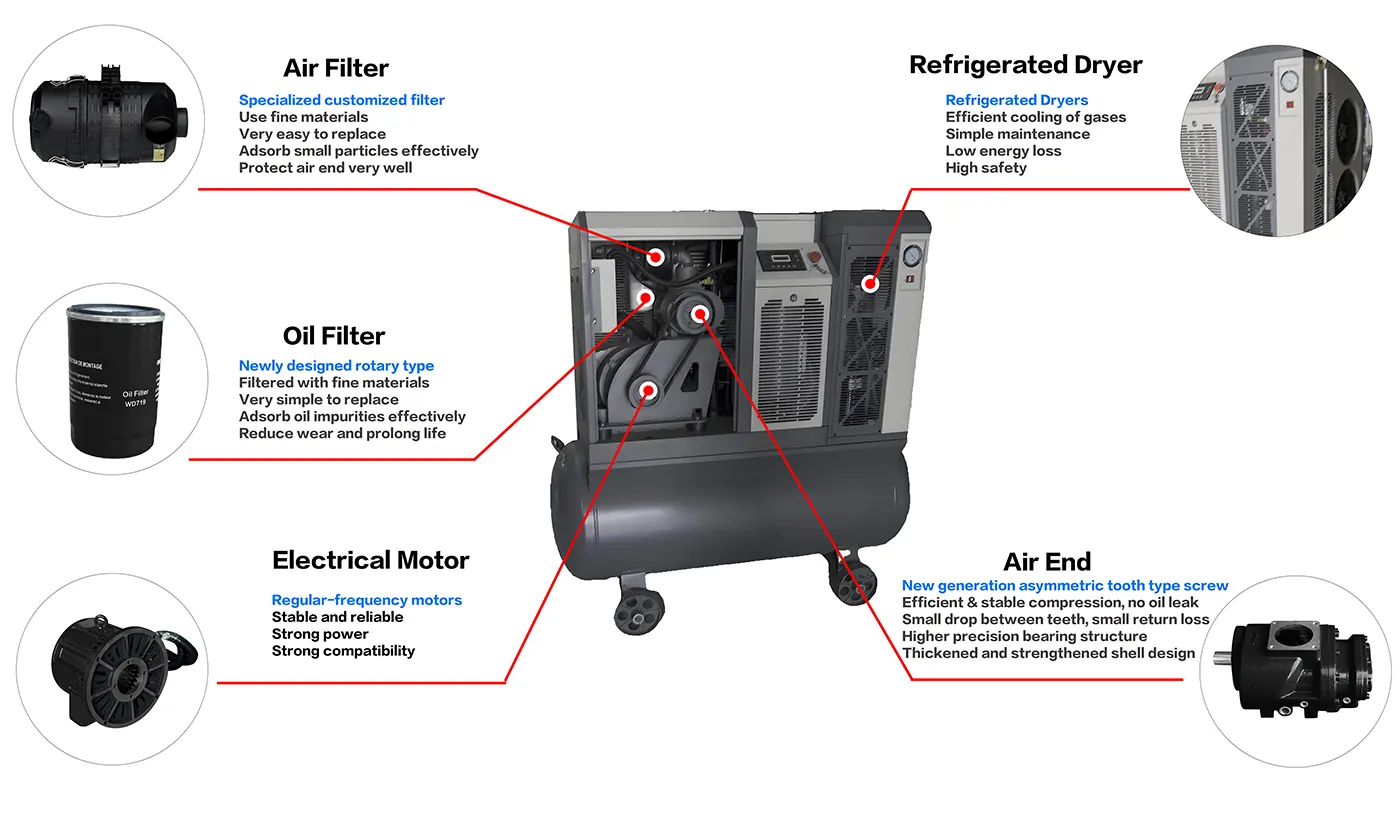

Here is the new B-XG7.5A Small Portable Rotary Screw Air Compressor which aims to be convenient and portable. This mini yet mighty compressor is equipped with a 7.5 HP motor coupled with a 210L air receiver to give regardless performance for several applications. Operating at a pressure of 0.8MPa and providing an airflow of 0.67m3/min, it is suitable for driving pneumatic instruments operating in workshops, construction sites, and home improvement processes. The portable design provided for this model also completes the solution needed where compressed air is required on the move.

B-XG7.5A

- Pressure(MPa): 0.8

- Exhaust Volume(m³/min): 0.67

- Power(KW/HP): 5.5/7.5

- Dimension(mm): 1250*480*1060

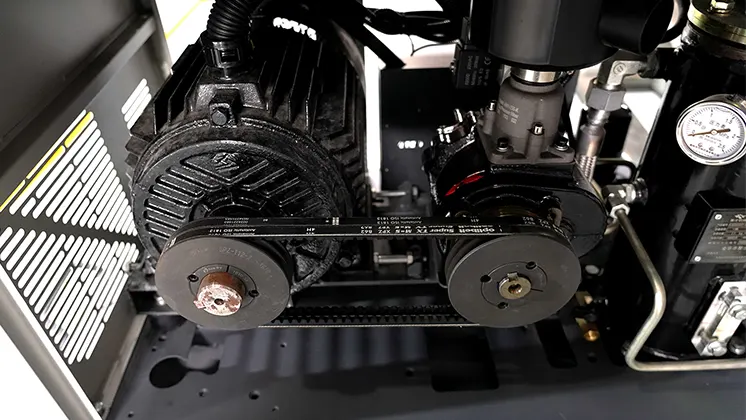

- Drive Mode: Belt

- Weigt(kg): 190

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Gas Tank(L): 210, Available for Customization

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

B-XG15AL

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 1.5-1.3

-

Power(KW/HP): 11/15

-

Dimension(mm): 1500*700*1600

-

Drive Mode: Belt

-

Weigt(kg): 510

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 430, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-XG20A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 2.3

-

Power(KW/HP): 15/20

-

Dimension(mm): 1160*660*1660

-

Drive Mode: Belt

-

Weigt(kg): 350

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 430, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-XG10AL

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1550*580*1230

-

Drive Mode: Belt

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 300, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

B-XG7.5A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 0.67

-

Power(KW/HP): 5.5/7.5

-

Dimension(mm): 1250*480*1060

-

Drive Mode: Belt

-

Weigt(kg): 190

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 210, Available for Customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

JX-15APMX-11KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Z-G10A-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE

Get In Touch