Portable Rotary Screw Air Compressor Manufacturers

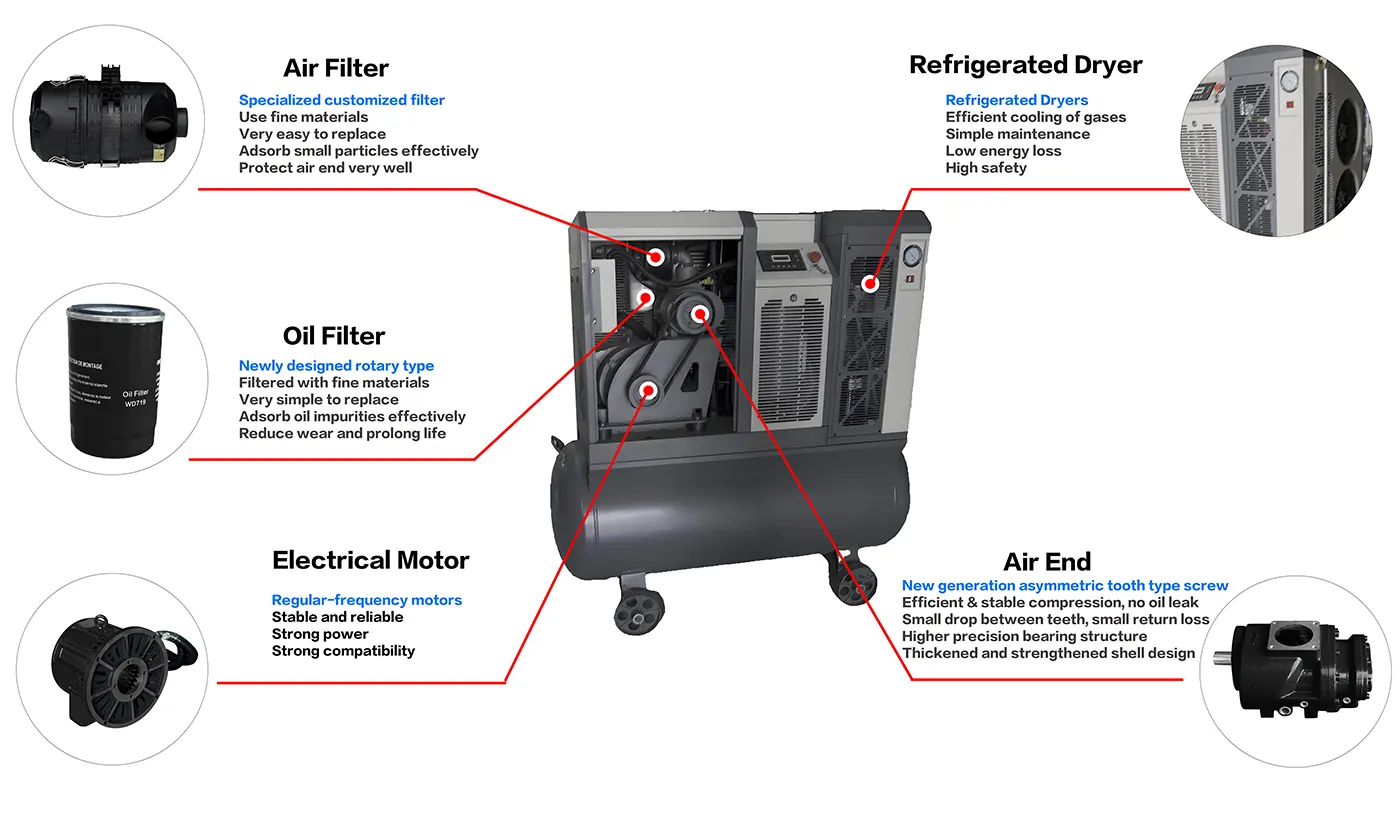

Let me present you the B-XG5.5A Portable Rotary Screw Air Compressor that supports effectiveness and durability. This is a powerful and compact compressor designed for versatility the unit uses a 5.5 HP motor and comes equipped with a 210L air receiver. The performance parameters are 0.8 MPa, and it flows at a rate that is 0.48 m³/min which makes it quite useful for the operation of pneumatic tools in workshops constructions, and small industries. It is portable meaning that you can move it from one place to another and get reliable compressed air where you want it. Thus you should consider B-XG5.5A as one of the best air compression equipment in the market to go for.

- Pressure(MPa): 0.8

- Exhaust Volume(m³/min): 0.48

- Power(KW/HP): 4/5.5

- Dimension(mm): 1250*480*1060

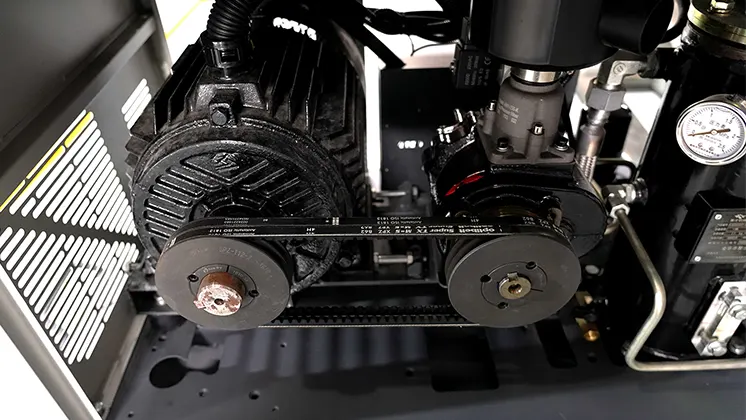

- Drive Mode: Belt

- Weigt(kg): 188

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Gas Tank(L): 210, available for customization

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1500*540*1120

-

Drive Mode: Belt

-

Weigt(kg): 245

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 250, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1550*580*1230

-

Drive Mode: Belt

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 300, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

-

Dimension(mm): 1160*660*1660

-

Drive Mode: Belt

-

Weigt(kg): 340

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 330, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 1.5-1.3

-

Power(KW/HP): 11/15

-

Dimension(mm): 1500*700*1600

-

Drive Mode: Belt

-

Weigt(kg): 510

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Gas Tank(L): 430, available for customization

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE