Three phase Induction Motor

Compressed air moves with you!

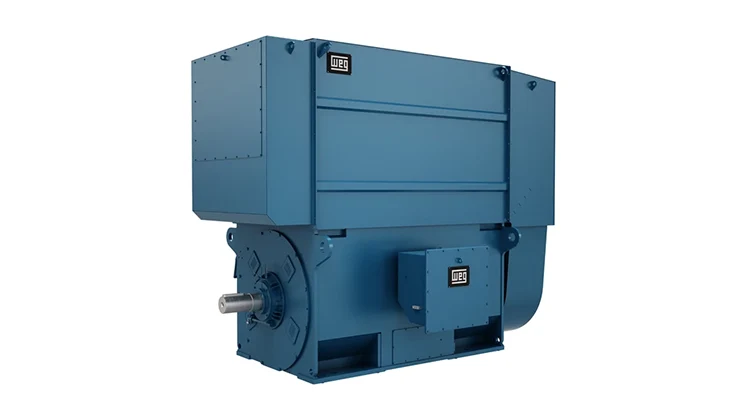

HGF Three-phase Induction Motor

The HGF Three Phase Induction Motor is intended for performance and durability for various sectors. The rated output power of this motor is specified as ranging between 355 and 2800 kW; the aforementioned motor is operated in working conditions where the reliability and work performance of the equipment are relatively high. It comes with a frequency range of fifty-sixty hertz and a voltage range of 2, 300Volts to 6, 600Volts. This type of motor is well suitable for use in the manufacturing industries, and mining among others because the HGF motor is designed to operate under tough conditions.

HGF-Three phase Induction Motor

- Rated Output: 355 kW~2800 kW

- Number of Poles: 2 ~12

- Frequency: 50/60 Hz

- Voltage: 2,300V~6,600 V

- Service Factor: 1.00

- Insulation Class: F (DT 80 K)

- Degree of Protection: IP55

- Mounting: Vertical or Horizontal

- Enclosure Material: FC-200 cast iron

- Cooling Method: TEFC (IC411) – Totally Enclosed Fan Cooled

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

W60 Vertical Line Three

-

Rated output: 1,000 up to 7,500 kW

-

Number of poles: 10 up to 18

-

Frame: 630, 710 and 900

-

Voltage: 2,300 up to 13,800 V

-

Frequency: 50 or 60 Hz

-

Mounting: Vertical

VIEW MORE

W60 Three-phase Induction WEG Motor

-

Rated output: 1,000 up to 7,500 kW

-

Number of poles: 10 up to 18

-

Frequency: 50 Hz/60 Hz

-

Frame: 630, 710 and 900

-

Voltage: 2,300 up to 13,800 V

-

Mounting: vertical

-

Service Factor: 1.00

-

Cooling Method: IC01, IC611 and IC81W

VIEW MORE

HGF-Three phase Induction Motor

-

Rated Output: 355 kW~2800 kW

-

Number of Poles: 2 ~12

-

Frequency: 50/60 Hz

-

Voltage: 2,300V~6,600 V

-

Service Factor: 1.00

-

Insulation Class: F (DT 80 K)

-

Degree of Protection: IP55

-

Mounting: Vertical or Horizontal

-

Enclosure Material: FC-200 cast iron

-

Cooling Method: TEFC (IC411) – Totally Enclosed Fan Cooled

VIEW MORE

MASTER Series Large Induction Motors

-

Output: up to 50,000 kW

-

Frequency: 50 or 60 Hz

-

Voltage: 220 to 13,800 V

-

Frame: 280 to 1800 (IEC)

-

Speed: 3,600 to 300 rpm

-

Rotor: Squirrel cage

-

Insulation Class: F or H

-

Mounting: Horizontal or vertical

-

Bearing: Ball bearing or sleeve bearing

-

Degree of Protection: IP23, IP24(W), IP55, IP56 or IP65

VIEW MORE

You May Also Like

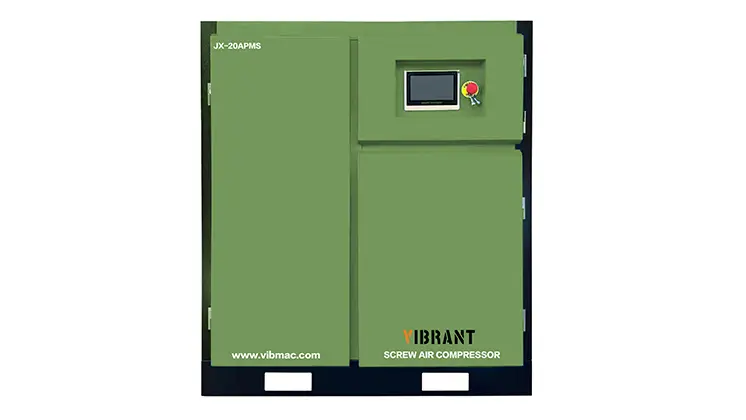

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

JX-15APMX-11KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Z-G10A-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE

Get In Touch