Variable Speed Air Handler With Single Stage Compressor

Intelligent power on your side!

Variable Speed Air Compressor

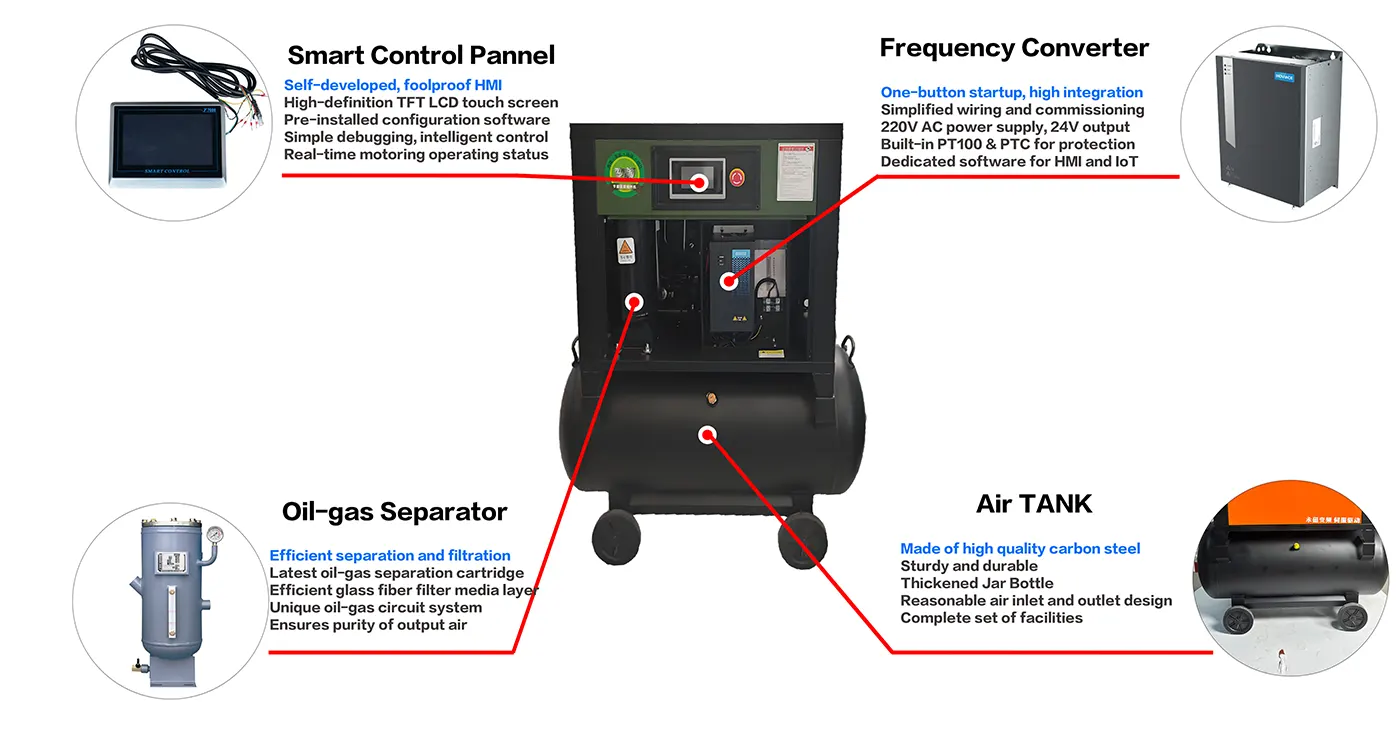

The Z-XG6APM Variable Speed Air Handler with Single Stage Compressor is portable for applications where the control of airflow rate and pressure is critical. It has a single-stage compressor and can work with variable frequency to achieve stable and accurate airflow for many applications in industrial and commercial applications. The 6 HP (4.5 kW) motor along with the 180 liters air receiver provides a means of efficient air delivery and is the least noisy hence suitable for indoor applications where excessive noise is frowned upon.

Z-XG6APM-4.5KW

- Pressure(MPa): 0.8

- Exhaust Volume(m3/min): 0.68

- Power(KW/HP): 4.5/6

- Dimension(mm): 1100*500*1150

- Noise dB(A): ≤58±2

- Weigt(kg): 155

- Pipe Diameter: G1/2

- Startup Mode: Frequency Conversion Start

- Gas Tank(L): 180, available for customization

- Power Supply: 380V/50HZ, or 220V, available for customization

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

Z-XG10APM-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 1.1

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 1250*600*1380

-

Noise dB(A): ≤62±2

-

Weigt(kg): 208

-

Pipe Diameter: G1/2

-

Startup Mode: Frequency Conversion Start

-

Gas Tank(L): 230, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

Z-XG6APM-4.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 0.68

-

Power(KW/HP): 4.5/6

-

Dimension(mm): 1100*500*1150

-

Noise dB(A): ≤58±2

-

Weigt(kg): 155

-

Pipe Diameter: G1/2

-

Startup Mode: Frequency Conversion Start

-

Gas Tank(L): 180, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

Z-SG10APM

-

Pressure(MPa): 0.8

-

FAD(m³/min): 1.1

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 1000*500*950

-

Noise dB(A): ≤62±2

-

Weigt(kg): 115

-

Pipe Diameter: G1/2*2

-

Startup Mode: Direct Start

-

Gas Tank(L): 230, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

Z-G5.5A-4KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 0.62

-

Power(KW/HP): 4/5.5

-

Dimension(mm): 1170*510*1090

-

Noise dB(A): ≤62±2

-

Weigt(kg): 154

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Gas Tank(L): 180, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

You May Also Like

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

JX-15APMX-11KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

VIEW MORE

Z-G10A-7.5KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.0

-

Power(KW/HP): 7.5/10

VIEW MORE

Get In Touch