Screw Compressor Air

Air compressors that can help companies solve their problems.

Fixed Speed Tank-mounted Screw Air Compressor

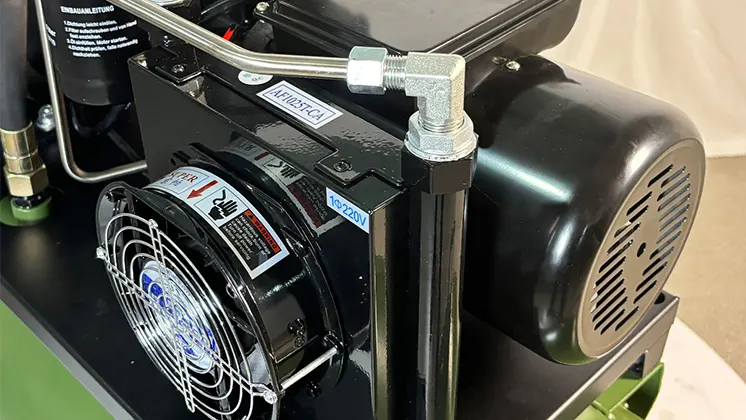

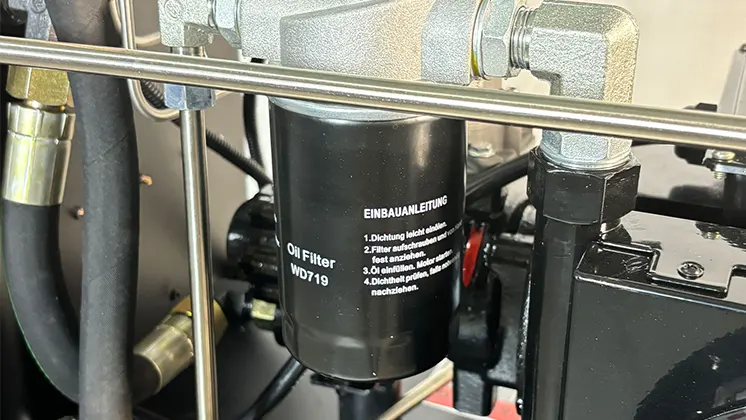

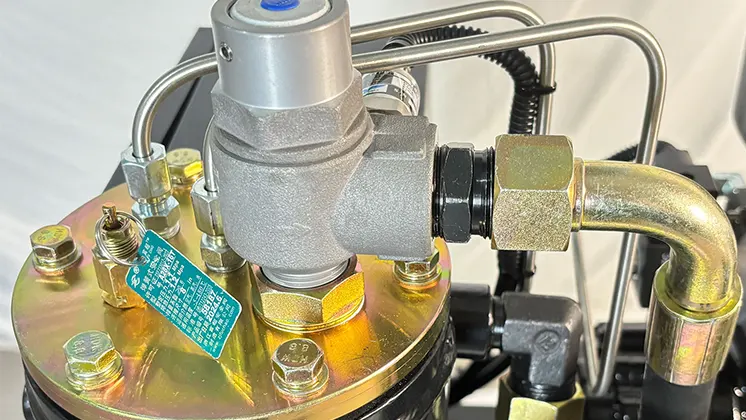

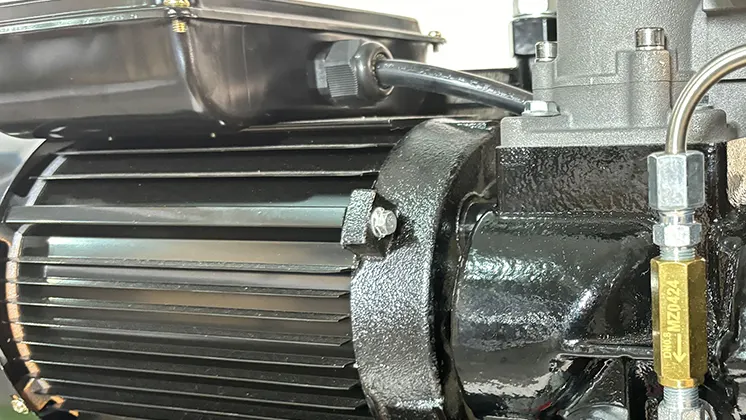

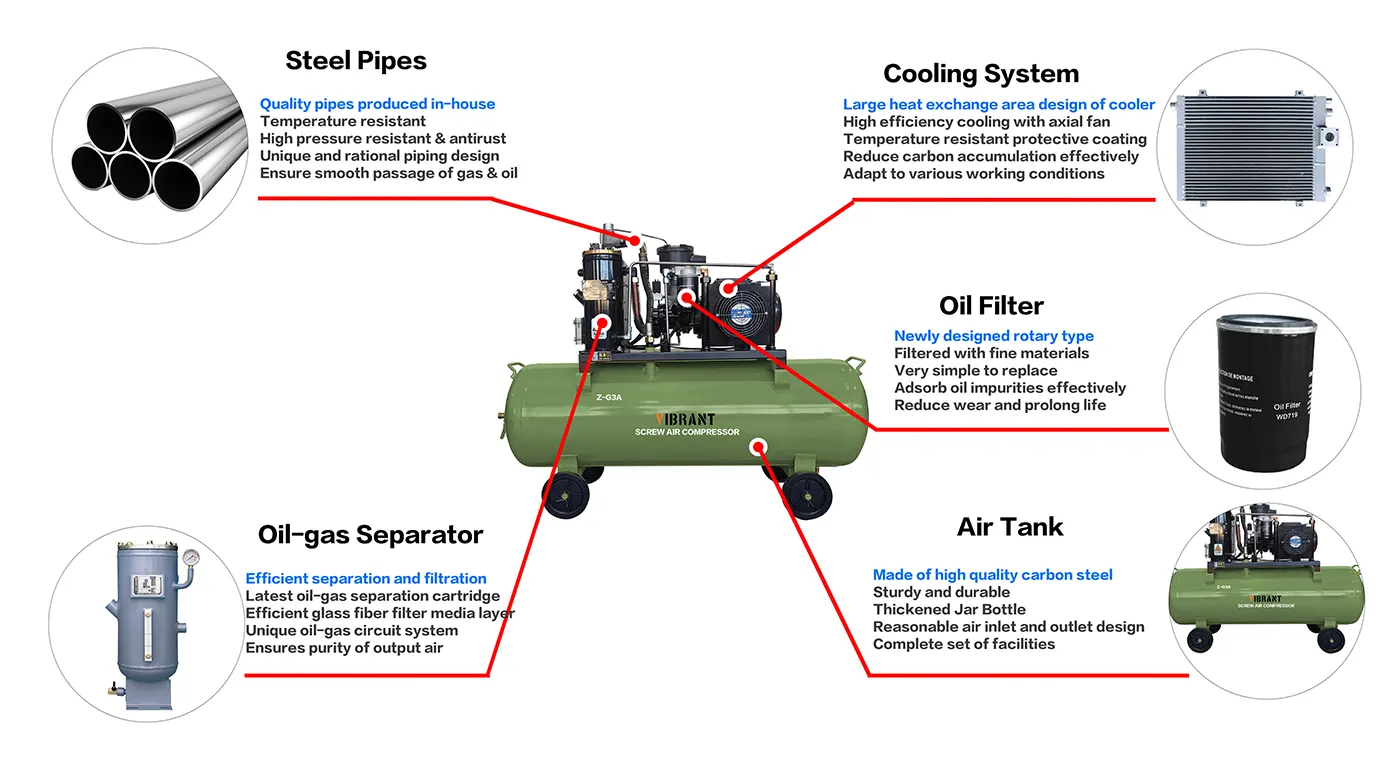

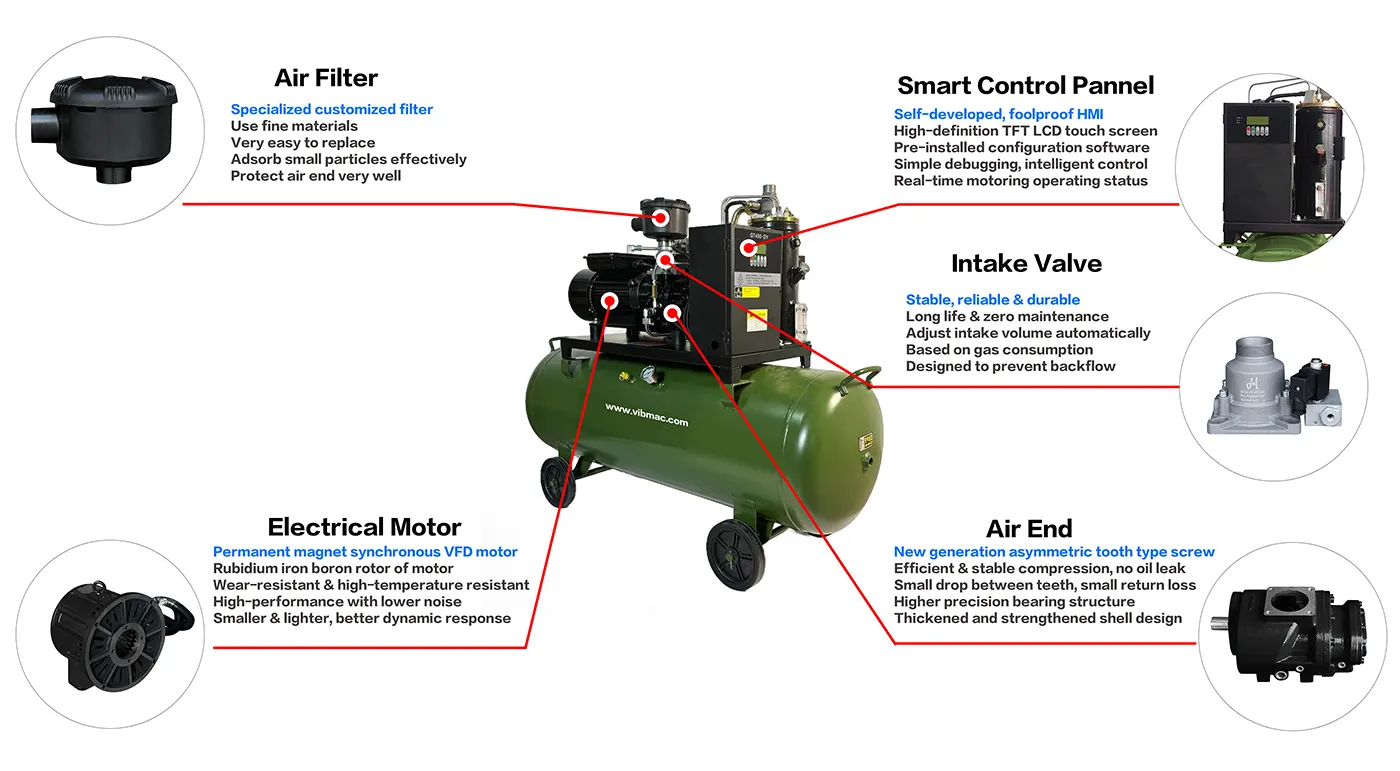

The Z-G10A-7.5KW Screw Compressor Air is one the most powerful but powerful air compressors which can be used by industries and workshops. This model also has a 7.5 kW (10 HP) motor to make it very powerful, efficient as well as also well-made. Therefore, the 230liter air receiver is sufficient to maintain a steady air supply when used to address the different median to heavy usage. Due to a small ultralight design together with high motor productivity, the constant supply of compressed air appropriate for numerous uses is provided.

Z-G10A-7.5KW

- Pressure(MPa): 0.8

- Exhaust Volume(m³/min): 1.0

- Power(KW/HP): 7.5/10

- Dimension(mm): 1400*510*1090

- Noise dB(A): ≤68±2

- Weigt(kg): 177

- Pipe Diameter: G1/2

- Startup Mode: Direct Start

- Gas Tank(L): 230, available for customization

- Power Supply: 380V/50HZ, or 220V, available for customization

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

Z-G3A-2.2KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 0.3

-

Power(KW/HP): 2.2/3

-

Dimension(mm): 1340*450*1030

-

Noise dB(A): ≤60±2

-

Weigt(kg): 116

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Gas Tank(L): 160, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

Z-G5.5A-4KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m3/min): 0.62

-

Power(KW/HP): 4/5.5

-

Dimension(mm): 1170*510*1090

-

Noise dB(A): ≤62±2

-

Weigt(kg): 154

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Gas Tank(L): 180, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

Z-SG10APM

-

Pressure(MPa): 0.8

-

FAD(m³/min): 1.1

-

Power(KW/HP): 7.5/ 10

-

Dimension(mm): 1000*500*950

-

Noise dB(A): ≤62±2

-

Weigt(kg): 115

-

Pipe Diameter: G1/2*2

-

Startup Mode: Direct Start

-

Gas Tank(L): 230, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

Z-SG6APM

-

Pressure(MPa): 0.8

-

FAD(m³/min): 0.68

-

Power(KW/HP): 4.5/ 6

-

Dimension(mm): 1000*500*950

-

Noise dB(A): ≤58±2

-

Weigt(kg): 105

-

Pipe Diameter: G1/2*2

-

Startup Mode: Direct Start

-

Gas Tank(L): 230, available for customization

-

Power Supply: 380V/50HZ, or 220V, available for customization

VIEW MORE

You May Also Like

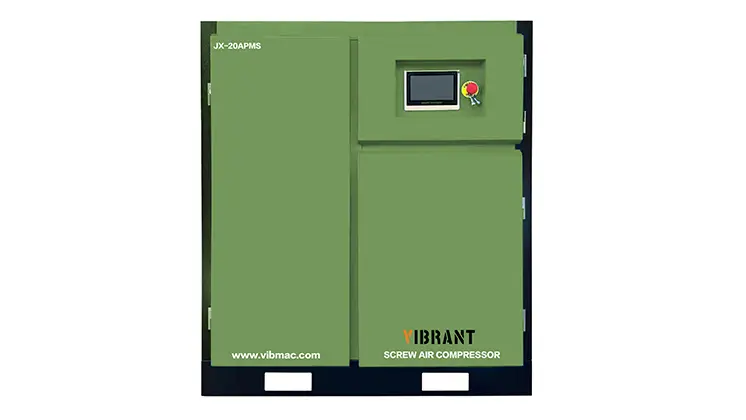

JX-20APMS-20HP/15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.3~1.7

-

Power(KW/HP): 15/20

VIEW MORE

JX-20APMX-15KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 2.4~1.8

-

Power(KW/HP): 15/20

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

VIEW MORE

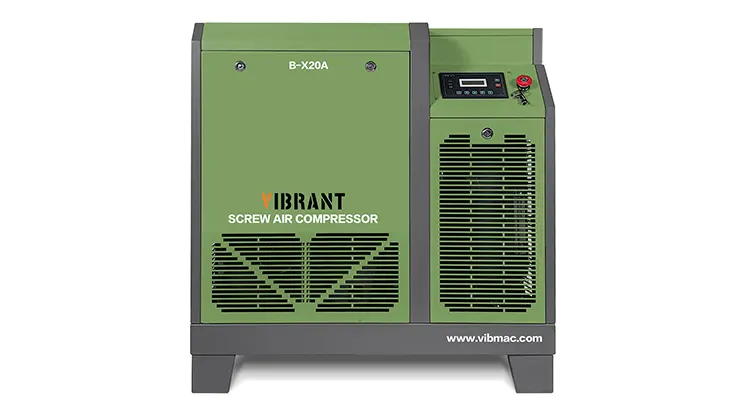

B-X20A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 2.3

-

Power(KW/HP): 15/20

VIEW MORE

Get In Touch