Large Air Compressor

Air compressors that can help companies solve their problems.

Fixed Speed Air Compressor

The working motor of fixed speed air compressor is always running at a fixed voltage, the motor drives the rotating screw to inhale pressurized air with a constant speed, the motor is always running at a constant rotational speed, even under very small load conditions. With the consumption of high-pressure air in the storage tank, when the pressure is less than the set value, the control system will control the motor to restart the pressurization, and after pressurization, it will stop again.

JX-5.5AS-4KW

- Pressure(MPa): 0.8

- Exhaust Volume(m³/min): 0.62

- Power(KW/HP): 4/5.5

- Dimension(mm): 800*500*750

- Noise dB(A): ≤60±2

- Weigt(kg): 103

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-50AS-50HP-37KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 650

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-30AS-22KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 3.5~2.4

-

Power(KW/HP): 22/30

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 430

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

-

Dimension(mm): 1150*750*960

-

Noise dB(A): ≤65±2

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-10AS-7.5KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.2~0.7

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 900*650*860

-

Noise dB(A): ≤63±2

-

Weigt(kg): 190

-

Pipe Diameter: G1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

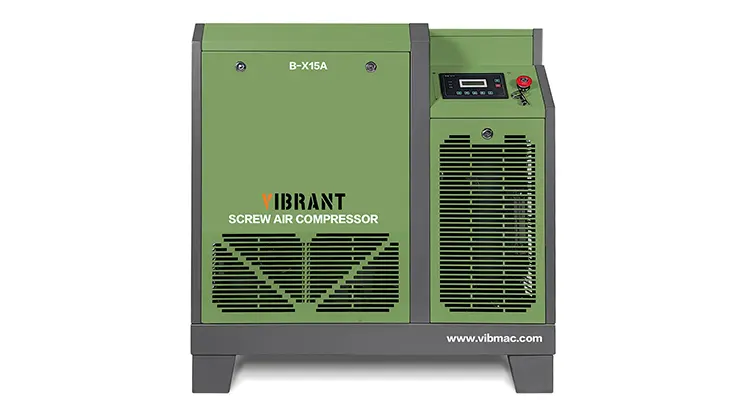

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

B-XG7.5A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 0.67

-

Power(KW/HP): 5.5/7.5

VIEW MORE

JX-40APML

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 2.5/2.2

-

Power(KW/HP): 30/40

VIEW MORE

JX-75APMX-55KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

VIEW MORE

Get In Touch