Fixed Speed Screw Air Compressor

Air compressors that can help companies solve their problems.

Fixed Speed Air Compressor

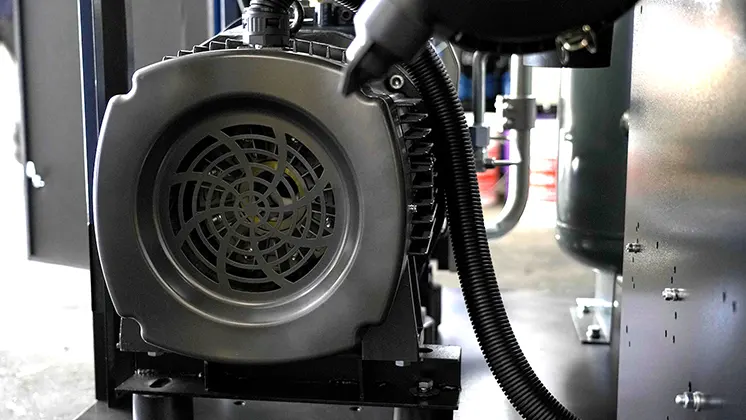

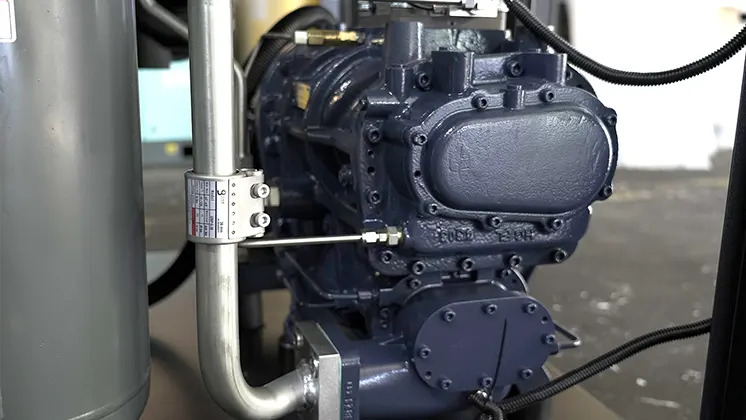

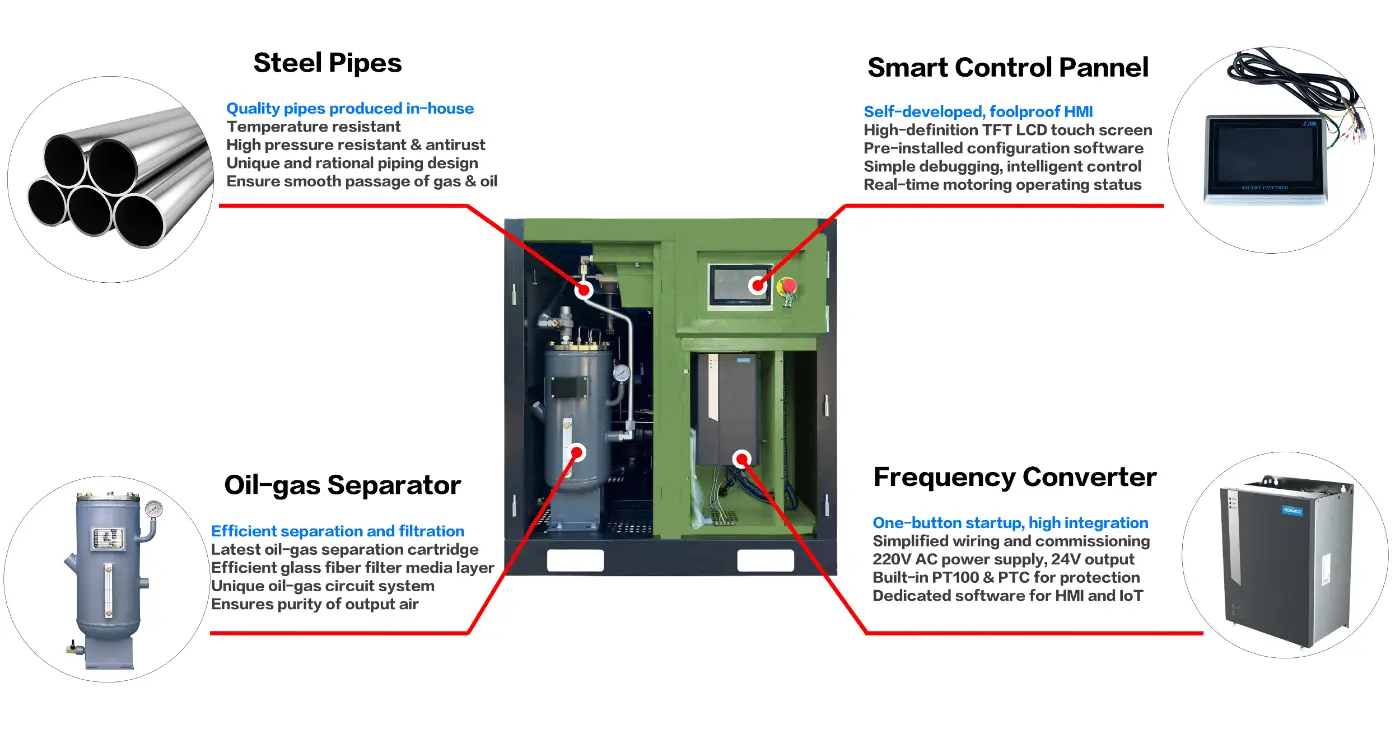

Allow me to introduce you to Fixed Speed Screw Air Compressor model JX-10AS – It is our most efficient series of air compressors for any ever versatile sector. Offered with a motor power of 10 HP (7.5 kW), this compressor design has improved performance and variations in difficult functional conditions. The air-cooled design can make the device work properly irrespective of the climatic condition of the area where it is operating, provided climatic conditions of 46 degrees Celsius otherwise.

JX-10AS-7.5KW

- Pressure(MPa): 0.7~1.3

- Exhaust Volume(m³/min): 1.2~0.7

- Power(KW/HP): 7.5/10

- Dimension(mm): 900*650*860

- Noise dB(A): ≤63±2

- Weigt(kg): 190

- Pipe Diameter: G1/2

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

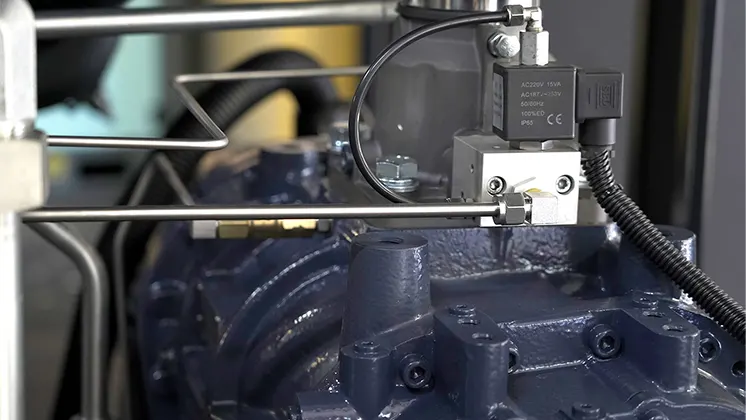

Intelligent

Get a quote now

Similar Products

JX-50AS-50HP-37KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 650

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60AS-60HP-45KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 7.3~6.2

-

Power(KW/HP): 45/60

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 700

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-15AS-11KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

-

Dimension(mm): 1150*750*960

-

Noise dB(A): ≤65±2

-

Weigt(kg): 320

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-30AS-22KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 3.5~2.4

-

Power(KW/HP): 22/30

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 430

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X15A

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

B-XG20AL

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 2.3-2.1

-

Power(KW/HP): 15/20

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-100APMS-100HP/75KW

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

Get In Touch