11KW 15hp Fixed Speed Air Compressor

Air compressors that can help companies solve their problems.

Fixed Speed Air Compressor

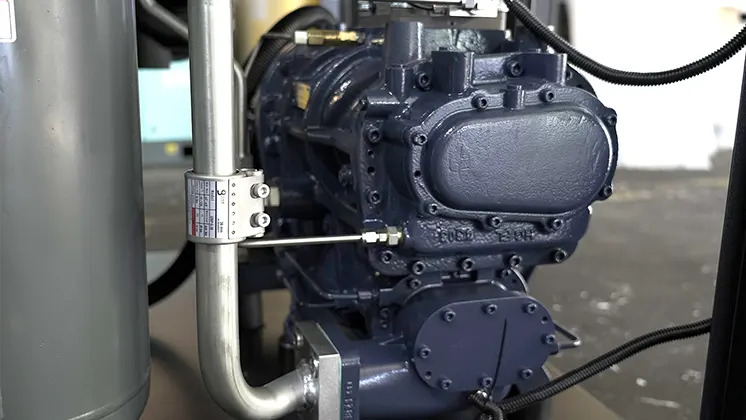

Another example of a fixed fixed-speed air compressor is the JX-15AS-11KW Fixed Speed Air Compressor is fixed fixed-speed air compressor that for assured reliability and performance for uses across industries. Although the fan is relatively small and directly connected to drive mode, it is still able to supply the continuous air requirement necessary for continuous operation.

JX-15AS-11KW

- Pressure(MPa): 0.7~1.3

- Exhaust Volume(m³/min): 1.7~1.0

- Power(KW/HP): 11/15

- Dimension(mm): 1150*750*960

- Noise dB(A): ≤65±2

- Weigt(kg): 320

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-40AS-40HP-30KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 460

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50AS-50HP-37KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 650

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

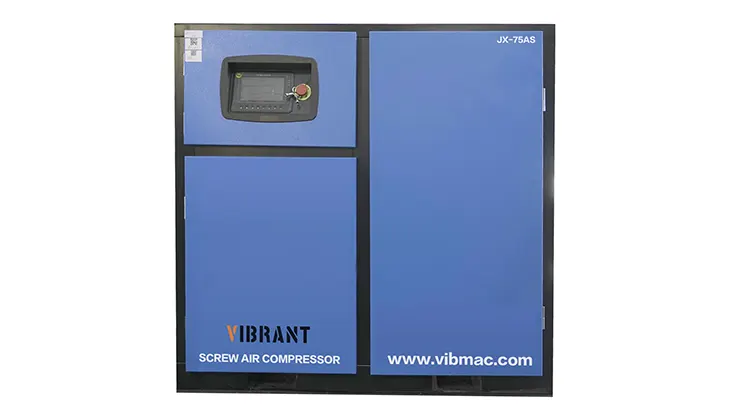

JX-75AS-55KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 9.4~6.1

-

Power(KW/HP): 55/75

-

Dimension(mm): 1700*1210*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 1100

-

Pipe Diameter: G2 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-20AS-15KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 2.4~1.6

-

Power(KW/HP): 15/20

-

Dimension(mm): 1150*750*960

-

Noise dB(A): ≤65±2

-

Weigt(kg): 340

-

Pipe Diameter: G3/4

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-XG20AL

-

Pressure(MPa): 0.8-1.0

-

Exhaust Volume(m³/min): 2.3-2.1

-

Power(KW/HP): 15/20

VIEW MORE

JX-100APMX-75KW

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

JX-15APML

-

Pressure(MPa): 1.6

-

FAD (m³/min): 0.9

-

Power(KW/HP): 11/15

VIEW MORE

JX-20APMLT

-

Pressure(MPa): 1.6/2.0

-

FAD (m³/min): 1.2/1.0

-

Power(KW/HP): 15/20

VIEW MORE

Get In Touch