Gas Air Compressor

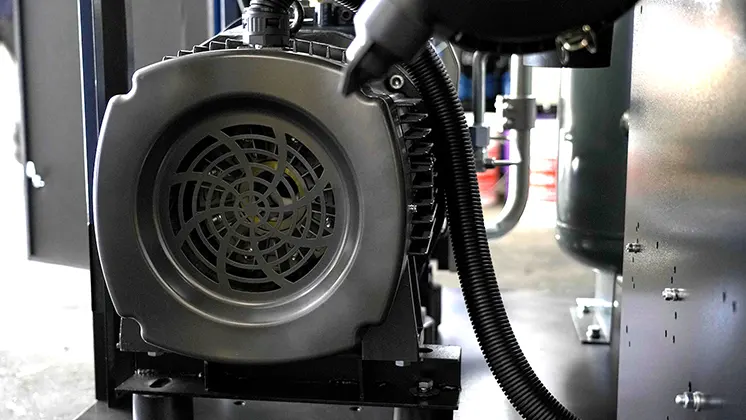

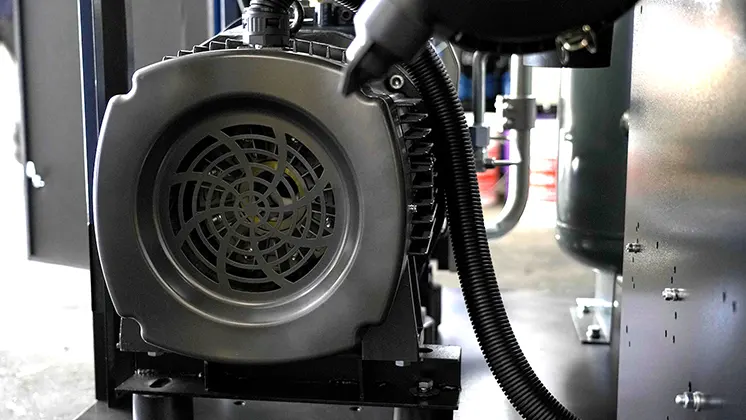

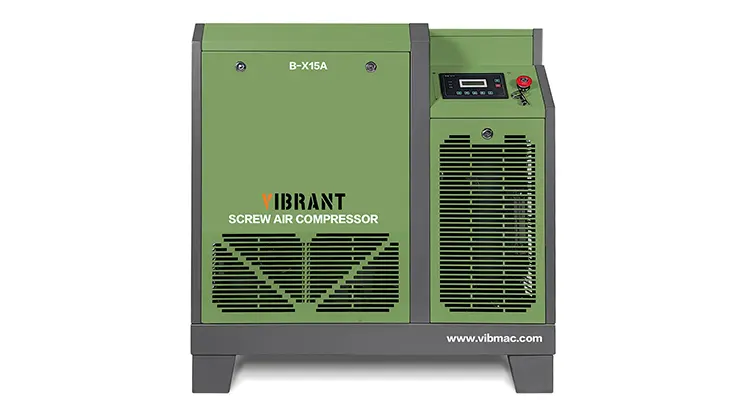

The JX-20AS Gas Air Compressor is designed to operate in toughness conditions without compromising its performance. The current model is a single-stage Lubricated air-cooled screw compressor that delivers quality as well as quantity of compressed air needed in various industrial and commercial processes.

- Pressure(MPa): 0.7~1.3

- Exhaust Volume(m³/min): 2.4~1.6

- Power(KW/HP): 15/20

- Dimension(mm): 1150*750*960

- Noise dB(A): ≤65±2

- Weigt(kg): 340

- Pipe Diameter: G3/4

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

This model operates at an exhaust pressure of 0.8 MPa and an exhaust air volume of 2.2 m³/min; here one can use it with pneumatic tools and other pneumatic devices. As it is intended to work in conditions to a maximum of environmental temperatures of 46 C this compressor meets all the optimum conditions that can be expected of it when placed under various conditions. Exhaust oil content is below 3 ppm and this makes it produce clean air output perfect for sensitive uses.

Long side: 1150mm, short side: 750mm; height: 960mm; The product weighs 340Kg, which makes its installation and connection to existing systems easy. The external aspect of the G3/4 outlet pipe in particular means that getting a direct connection to the air line is much easier.

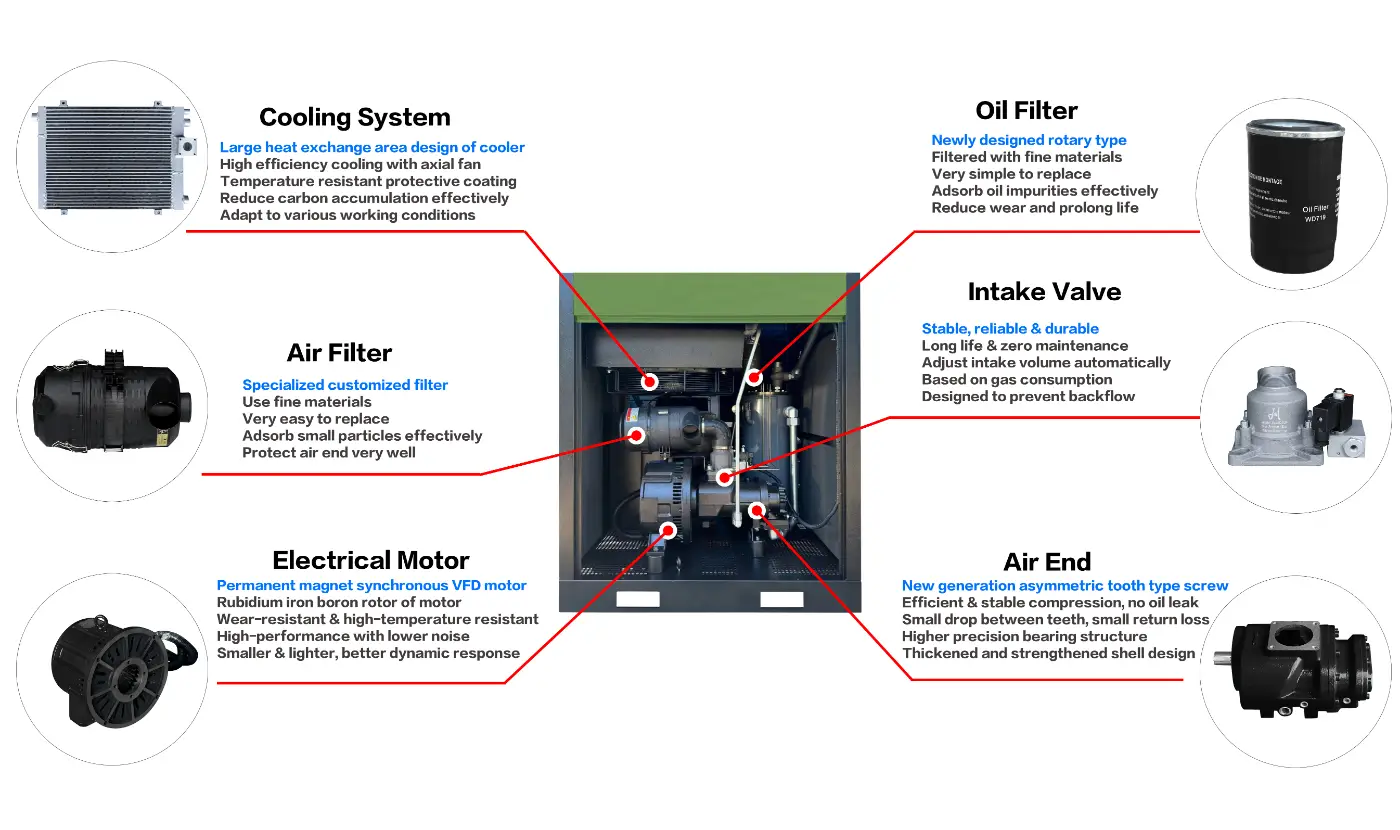

- Single Stage Compression: Fewer components flying around at the same time which means there is less wear to the system and therefore less English: maintenance is needed.

- Air-Cooled Operation: Functions within optimum temperature to enhance its high dependability besides higher effectiveness.

- Low Operating Noise: Designed for operating at ≤ 65 dB(a) for environments that require little or no noise.

- Direct Connection Drive Mode: The most crucial element in this sector is its capacity to provide power to other sectors without several losses to the supplied power.

- Customizable Power Supply: It can take 3-phase 380 V / 50Hz power input; The wiring diagrams are flexible in the way that some of them may be modified according to the customer’s preferences.

- High Operating Temperature Tolerance: Suitable for a specific high ambient temperature of 46°C to deliver optimum work.

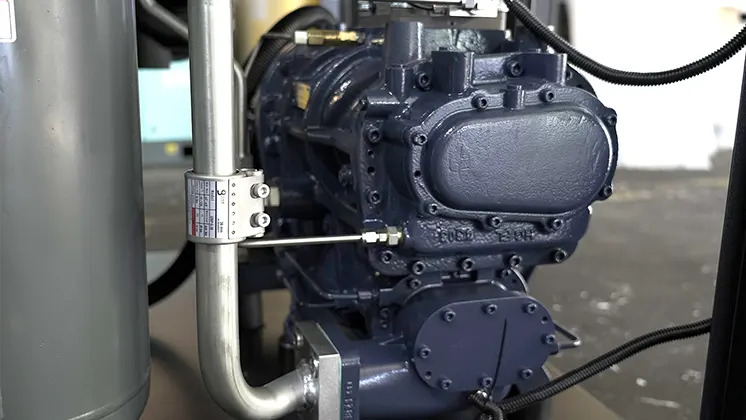

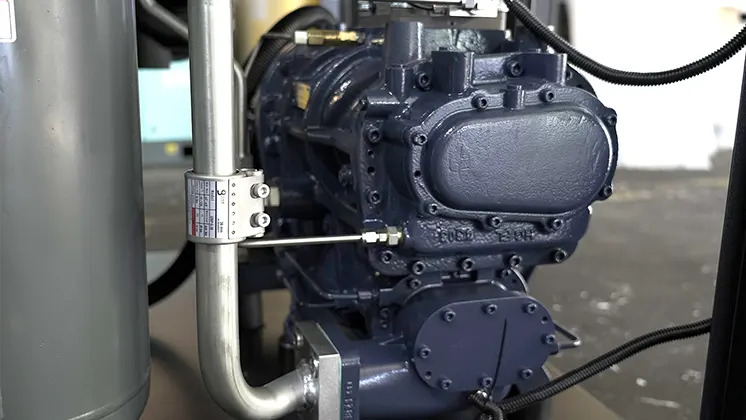

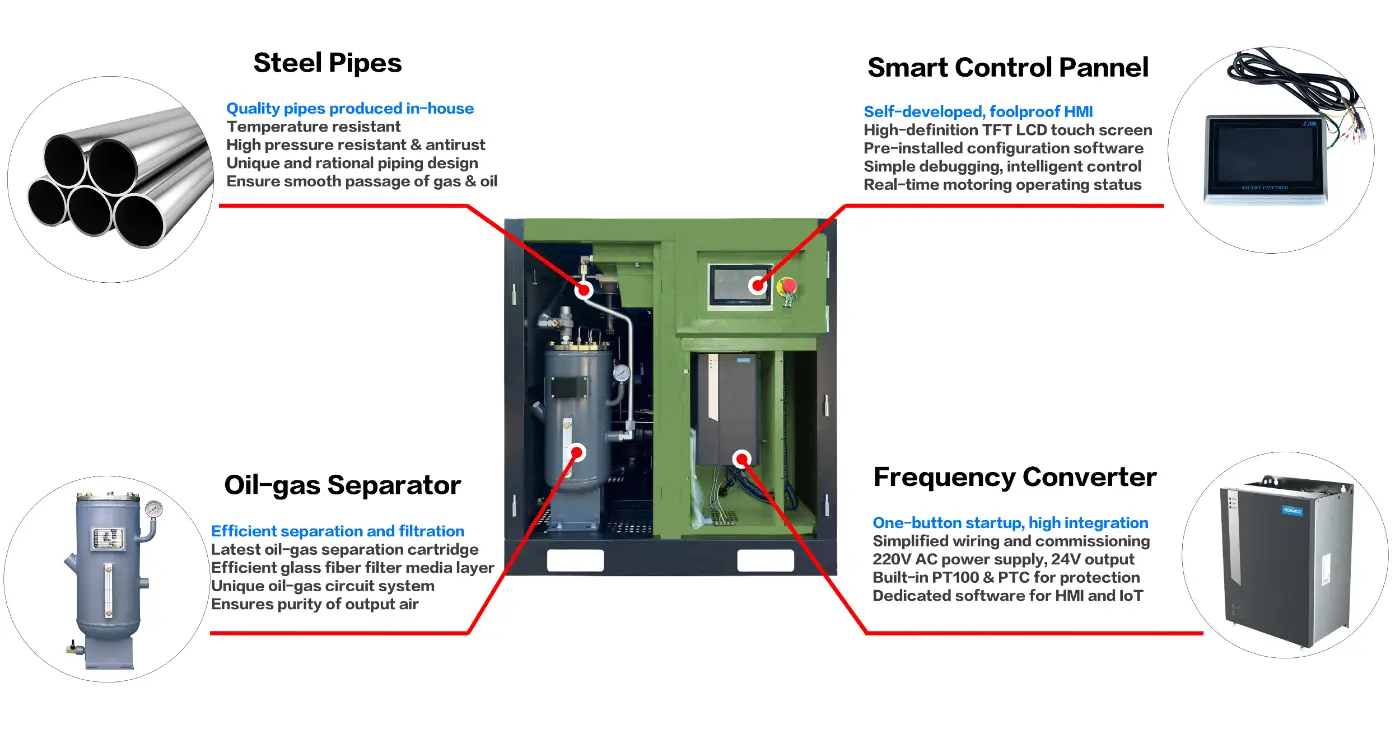

- Compressor Unit: That portion of the core system that is necessary to deliver not only the requisite discharge air compression at the various pressures it accomplishes this as well.

- Air Filters: Clean air is to be taken in order to make sure that there won’t be any sort of intrusive particles getting into the internal parts of this car to cause wear.

- Lubrication System: This contributes to the free operation of rubbing surfaces and the extension of serviceability of the compressor.

- Pressure Regulator: Able to maintain stability on its pressure output in a manner that none reaches the dangerous pressure as far as its operation is concerned.

- Piping and Fittings: Must be inspected frequently for the presence of any signs of leakages, or for any blockage in the airflow.

- Routine Maintenance: The other was based on the frequency of the lubricant check and replacement so that the compressor reliability would not be degraded.

- Environmental Considerations: Ensure that the installation place should be capable of accommodating maximum environmental temperatures.

- Pressure Monitoring: While going through the loop, make sure we carefully monitor the exhaust pressure because going high will put pressure on the compressor.

- Noise Level Management: Use Insulation measures if necessary in order to maintain a noise-free working environment in the laboratory.

- Manufacturing Plants: Suitable for use in operating various pneumatic tools and equipment in assembly lines in the industry.

- Energy and Power Plants: Ideally used in processes that need frequent use of compressed air at high pressure and quantity levels.

- Automotive Industry: Supplies air for use in several pneumatic tools during automobile construction and when repairing them.

- Heavy Machinery Operations: Demands accurate delivery of air for the operation of large machinery in the construction and mining sectors.

- HVAC Systems: They can be used in large HVAC systems where perhaps high pressure and steady airflow are most needed for the efficiency of the system.

| Item | Technical Parameter | |

| Unit Model | JX-20AS | |

| Exhaust Pressure (MPa) | 0.8 | |

| Exhaust Volume (m3/min) | 2.2 | |

| Cooling Mode | Air-cooled | |

| Maximum Environmental Temperature | 46℃ | |

| Number of Compression Stages | Single-stage | |

| Exhaust Oil Content | ≤3 ppm | |

| Operating Noise dB(a) ±2 | ≤65 | |

| Outlet Pipe Diameter | G3/4 | |

| Drive mode | Direct Connection | |

| Amount of Lubricant (L) | 8 | |

| Lubricant Grade | 46# | |

| Inspiratory State | Ordinary Temperature | Ordinary Temperature |

| Pressure (MPa) | 0.1013 | |

| Relative Humidity | 95% No Dew | |

| Motor | Rated Power (HP/KW) | 20/15 |

| Voltage (V)/ Frequency (Hz) | 380/50, can be customized | |

| Speed (RPM) | 2940 | |

| Startup Mode | Y-△ Start | |

| Protection Grade | IP23, can be customized | |

| Insulation Grade | F | |

| Usage Factor | 1.2 | |

| Overall Dimension L×W×H (mm) | 1150×750×960 | |

| Unit Weight (Kg) | 340 | |

Media error: Format(s) not supported or source(s) not found

Download File: https://www.vibmac.com/wp-content/uploads/2024/09/fixed_speed_air_compressor_JX_10AS_video.mp4?_=1

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 460

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 650

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 7.3~6.2

-

Power(KW/HP): 45/60

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 700

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 3.5~2.4

-

Power(KW/HP): 22/30

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 430

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 1.5

-

Power(KW/HP): 11/15

VIEW MORE

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE