Fixed Speed Air Compressors

Air compressors that can help companies solve their problems.

Fixed Speed Air Compressor

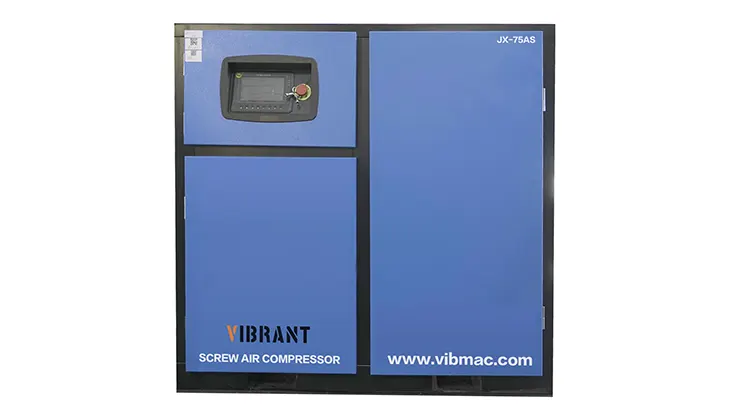

Find out that the JX-100AS Fixed Speed Air Compressor is suitable, more manageable, and the best air compressor for the industrial sectors. This single-stage air compressor has a stable performance since the maximum exhaust pressure is 0.8 MPa and the exhaust volume is 12.2 m3/min. The type is an air-cooled one and it is most efficient to supply all the conditions for which the maximum overloading of the ambient temperature to 46°C is expected.

JX-100AS-100HP/75KW

- Pressure(MPa): 0.7~1.3

- Exhaust Volume(m³/min): 12.4~9.1

- Power(KW/HP): 75/100

- Dimension(mm): 1700*1210*1550

- Noise dB(A): ≤80±2

- Weigt(kg): 1200

- Pipe Diameter: G2 1/2

- Startup Mode: Direct Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

Similar Products

JX-40AS-40HP-30KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1350*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 460

-

Pipe Diameter: G1

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-50AS-50HP-37KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 650

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-60AS-60HP-45KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 7.3~6.2

-

Power(KW/HP): 45/60

-

Dimension(mm): 1500*1000*1350

-

Noise dB(A): ≤78±2

-

Weigt(kg): 700

-

Pipe Diameter: G1 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

JX-75AS-55KW

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 9.4~6.1

-

Power(KW/HP): 55/75

-

Dimension(mm): 1700*1210*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 1100

-

Pipe Diameter: G2 1/2

-

Startup Mode: Direct Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

You May Also Like

B-X10A-16

-

Pressure(MPa): 1.6

-

Exhaust Volume(m³/min): 0.5

-

Power(KW/HP): 7.5/10

VIEW MORE

B-XG10A

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

JX-100APML2

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

JX-10APML

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

Get In Touch