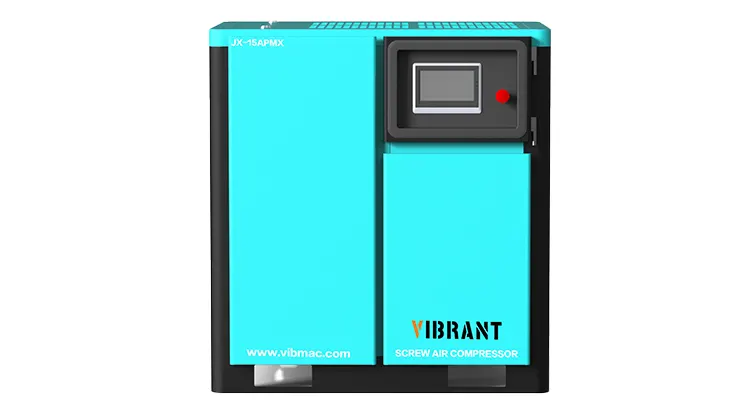

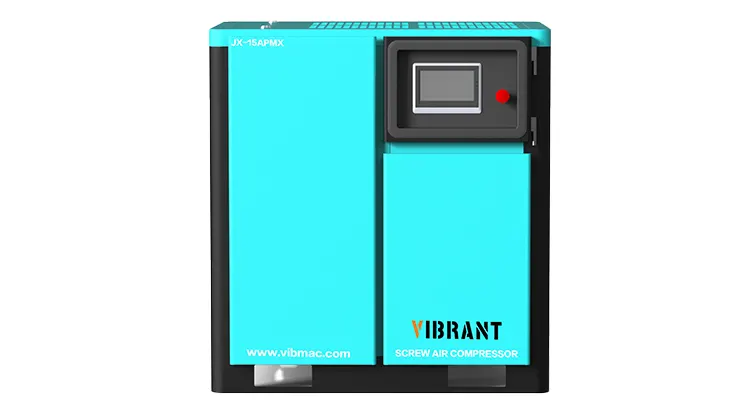

PM Air Compressor For Drilling JX-15APMX-11KW

The JX-15APMX PM Air Compressor for Drilling is principally designed which can effectively provide the desired performances in drilling applications. It provides the correct and steady air at a range that will support operations during conditions of high-demand states. Due to the fact that it is a heavy-duty air compressor, this type is appropriate for use by professions such as drilling.

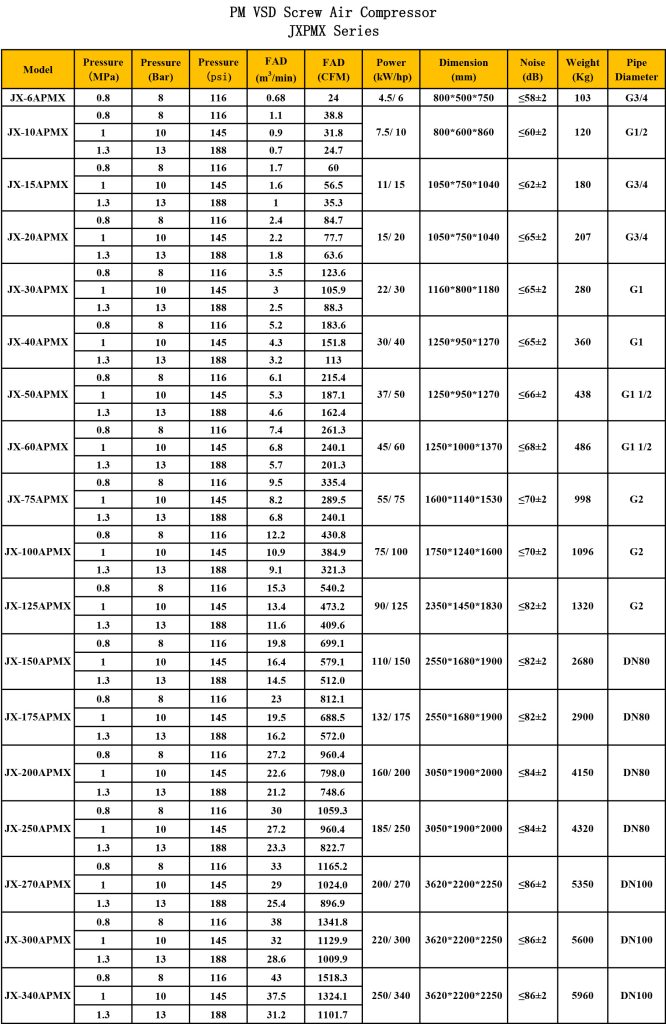

- Pressure(MPa): 0.8~1.3

- Exhaust Volume(m³/min): 1.7~1.0

- Power(KW/HP): 11/15

- Dimension(mm): 1050*750*1060

- Noise dB(A): ≤62±2

- Weigt(kg): 180

- Pipe Diameter: G3/4

- Startup Mode: Frequency Conversion Start

- Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

It has an exhaust pressure of 0.8 MPa and, an exhaust quantity of 1.7 m³/min, and can be used for many kinds of drilling work. The cooling mode defines the kind of air cooling, preserving normal working temperature with the maximum external temperature at 46 [°C]. It contains only single-stage compression and can provide air to maintain exhaust oil ≤ 3 ppm for the high operation mode.

The compressor was designed to generate a very low Acoustic Pressure of no more than 62 dB (a) ±2 and thus safe for areas with noise sensitivity. In heads up, it can blaze 12 liters of lubricant of Grade 46# when it is in a direct connection drive mode. The compressor employs a power supply system that has 3 phases of 380V/50Hz, which may be changed in the event of some complications. At normal temperature, it operates to the pressure of 0.1033 MPa and 60% relative humidity. It is a 15 HP or 11 kW motor, and for this, it is 3600 RPM, but with variable frequency starts to cut down the start current. It comes with a protection degree of IP23; other options regarding the build are optional, and insulation grade F for superior functionality. This type of air compressor is relatively large, measures 1700” x 750” x 1050”, and weighs 180 kg.

- Single-Stage Design: The air compression is also provided with improved efficiency to enable it to have low energy utilization while having high performance.

- Air-Cooled Cooling Mode: Controls the working temperature of the component thus leading to high efficiency and longer life span of the component.

- Low Operating Noise: Low noise designed although appropriate for application areas where noise is not a consideration.

- High Efficiency: It offers an adoption of 15 HP (11 kW) power and at the same time equally energy efficient.

- Flexible Power Supply Options: Energy is required in some operations to meet the cultural fulfillment of a given nation.

- Durable Construction: Constructed of high-grade materials and featuring only those components required especially in portions most likely to experience considerable use/abuse.

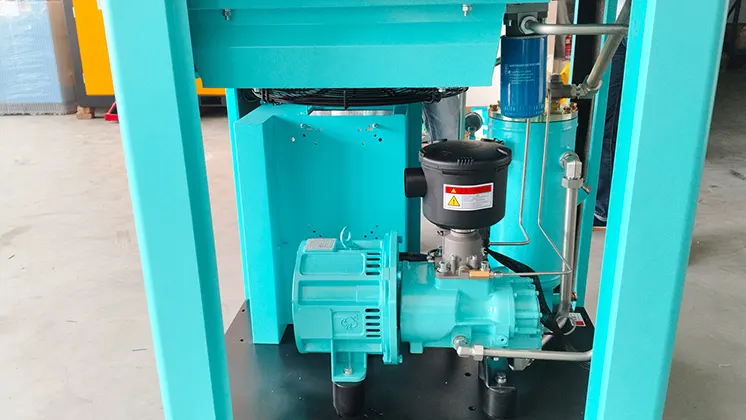

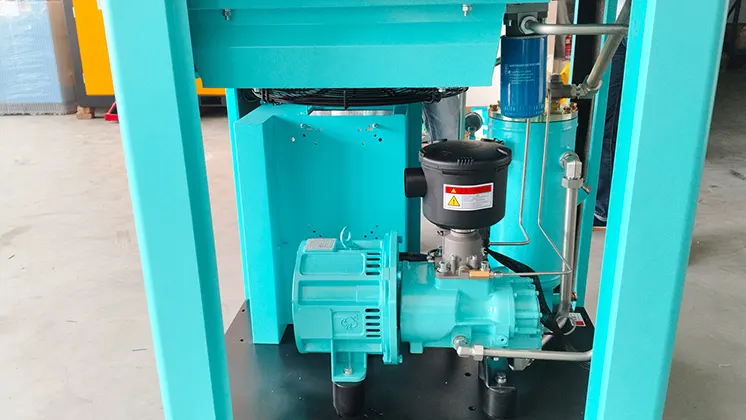

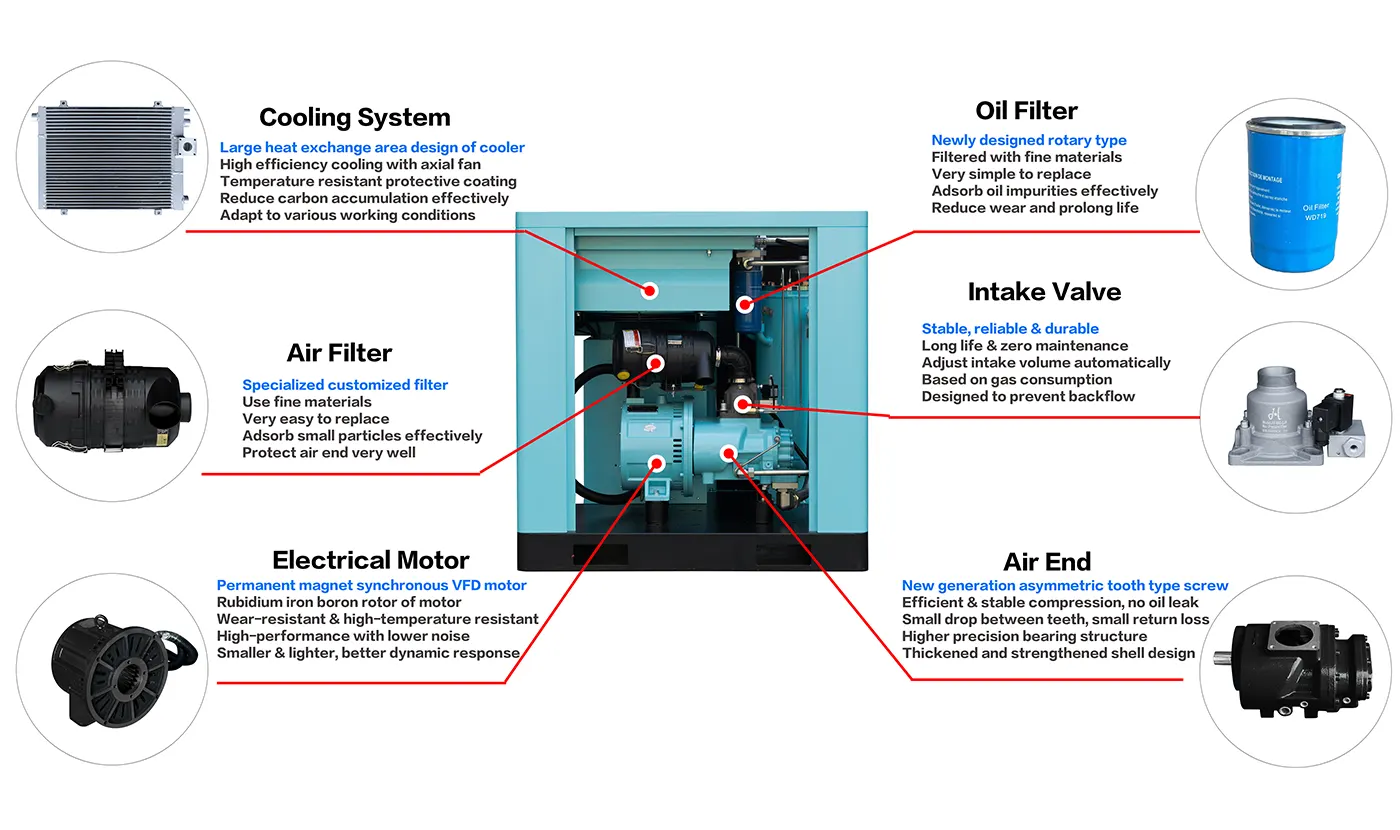

- Compressor Unit: A part of this device that compresses the air and has some parts that may need service sometimes.

- Air Cooling System: It does this in the sense that if it helps to regulate the temperature of the compressor in use, you know this is important.

- Lubrication System: SHOCK ABSORBERING SYSTEM which guarantees that the internal parts are most effective; is often checked and serviced.

- Oil Separator: This paper aims to identify the specific requirement out of the nine fundamental prerequisites to deliver high-purity compressed air contained in the study of Pascoe; the oil content of the compressed air.

- Filters: Most effective to protect the compressor from contaminants; always used when other parts are perfectly functioning but have to be changed in order to work as required.

- Drive Motor: The nature of specific compressor calls for reliability and performance at the required efficiency level to power the Compressor.

- Control Panel: It automatically controls the starting of the compressor and provides the display wherein the performance of the compressor is observed.

- Routine Maintenance: It is important to inspect and when necessary replace fluids, filters, and coolers to achieve maximum efficiency.

- Monitor Operating Conditions: The operating environment should be kept within some set parameters so that the electromechanical device does not overheat.

- Regular Inspections: It is necessary to perform periodic checks of all equipment and in particular check for wear on the wearing parts.

- Safety Protocols: Abide with all the safety measures recommended in the manufacturer’s manual, especially on aspects relating to electric parts and appropriate pressures.

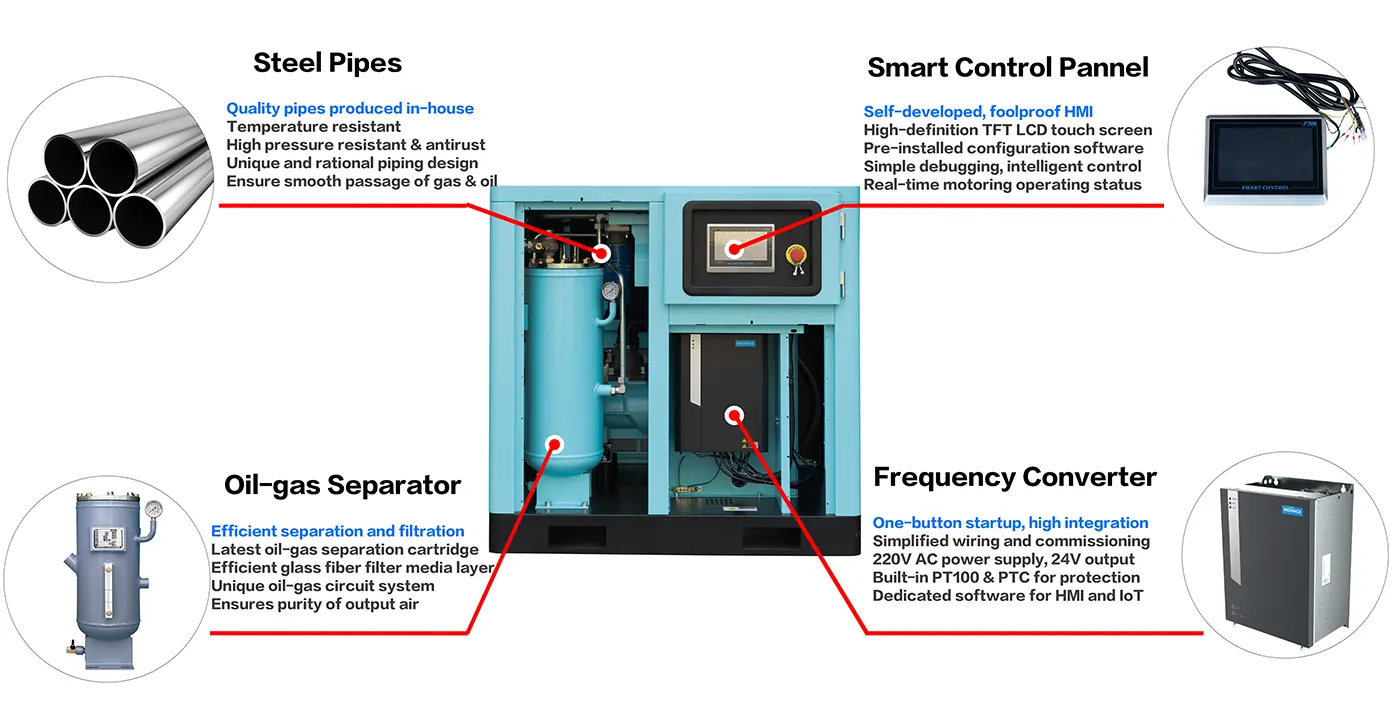

We conducted in-depth market research and longtime communication with our loyal customers to find out the problems and solve problems, then developed this energy-efficient JX-15APMX-15HP/11KW PM VSD screw air compressor through continuous technological innovation. In the R&D process of product design, prototyping, performance testing, and repeated optimization, every step is executed in strict accordance with international standards to ensure that each product meets the requirements of high standard industrial applications. With a strong R&D team and advanced production lines, we use the latest technology and materials to provide users with high-quality, high-performance air compressor products.

JX-15APMX-15HP/11KW screw air compressor is suitable for small and medium-sized compressed air systems in a lot of different factories, including:

- Drilling Operations: Applicable where the use of pneumatic drilling tools occurs in many processes.

- Construction Sites: Ideal for the supply of compressed air for construction plants and equipment as well as construction tools.

- Mining Applications: Properly useful to be used in drilling operations providing a mining environment.

- Water Well Drilling: For making provision for safe and qualified air during some of the water well drilling procedures.

- General Industry: Ideal in virtually all areas of the industrial sector where a supply of fresh air is provided.

| Item | Technical Parameter | |

| Unit Model | JX-15APMX | |

| Exhaust Pressure (MPa) | 0.8 | |

| Exhaust Volume (m3/min) | 1.7 | |

| Cooling Mode | Air-cooled | |

| Maximum Environmental Temperature | 46℃ | |

| Number of Compression Stages | Single-stage | |

| Exhaust Oil Content | ≤3 ppm | |

| Operating Noise dB(a) ±2 | ≤62 | |

| Outlet Pipe Diameter | G3/4 | |

| Drive mode | Direct Connection | |

| Amount of Lubricant (L) | 12 | |

| Lubricant Grade | 46# | |

| Power Supply | Tree-phase 380V/50Hz, can be customized | |

| Inspiratory State | Temperature (℃) | Ordinary Temperature |

| Pressure (MPa) | 0.1033 | |

| Relative Humidity | 60% | |

| Motor | Rated Power (HP/KW) | 15/11 |

| Voltage (V)/ Frequency (Hz) | 380/240 | |

| Speed (RPM) | 3600 | |

| Startup Mode | Variable Frequency Start | |

| Protection Grade | IP23, can be customized | |

| Insulation Grade | F | |

| Usage Factor | 1.2 | |

| Overall Dimension L×W×H (mm) | 1050×750×1060 | |

| Unit Weight (Kg) | 180 | |

Media error: Format(s) not supported or source(s) not found

Download File: https://www.vibmac.com/wp-content/uploads/2024/09/new_JX_20APMX_video_04.mp4?_=1

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

-

Dimension(mm): 1750*1240*1600

-

Noise dB(A): ≤70±2

-

Weigt(kg): 1096

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.1~4.6

-

Power(KW/HP): 37/50

-

Dimension(mm): 1250*950*1290

-

Noise dB(A): ≤66±2

-

Weigt(kg): 438

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 7.4~5.7

-

Power(KW/HP): 45/60

-

Dimension(mm): 1250*1000*1370

-

Noise dB(A): ≤68±2

-

Weigt(kg): 486

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.5~6.8

-

Power(KW/HP): 55/75

-

Dimension(mm): 1600*1140*1530

-

Noise dB(A): ≤70±2

-

Weigt(kg): 998

-

Pipe Diameter: G2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

Exhaust Volume(m³/min): 0.5

-

Power(KW/HP): 7.5/10

VIEW MORE

-

Pressure(MPa): 1.2-1.5

-

Exhaust Volume(m³/min): 0.7-0.63

-

Power(KW/HP): 7.5/10

VIEW MORE

-

Pressure(MPa): 0.8

-

Exhaust Volume(m³/min): 12.3

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE