Single Stage Air Compressors (PM VSD

Here introduces the JX-10APMS Single Stage Air Compressor (PM VSD), an instrument that has a longer service time and correct and effective integrated air compression function. They have a power rating of 10 HP (7.5 kW), therefore they may be used in automobile repair shops and industries among many others. On the cooling system, we have Air Cooled which will inform us that this machine works well with high-temperature conditions, and the highest acknowledged ambient temperature in this apparatus is 46 degrees Celsius.

- Pressure(MPa): 0.8/1.0/1.3

- Exhaust Volume(m³/min): 1.1/0.9/0.7

- Power(KW/HP): 7.5/10

- Dimension(mm): 800*600*860

- Noise dB(A): ≤63±2

- Weigt(kg): 112

- Pipe Diameter: G1/2

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

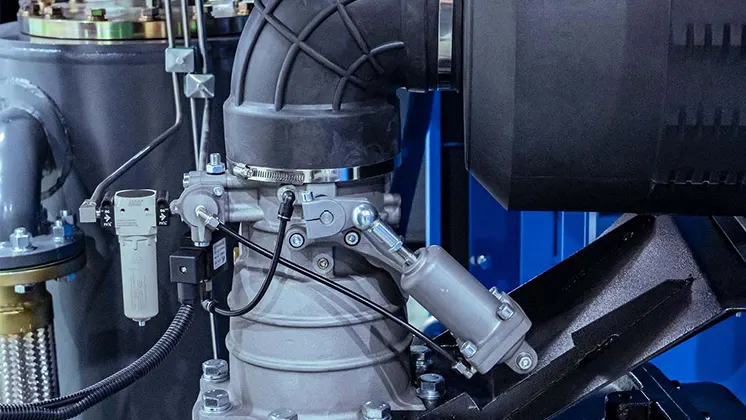

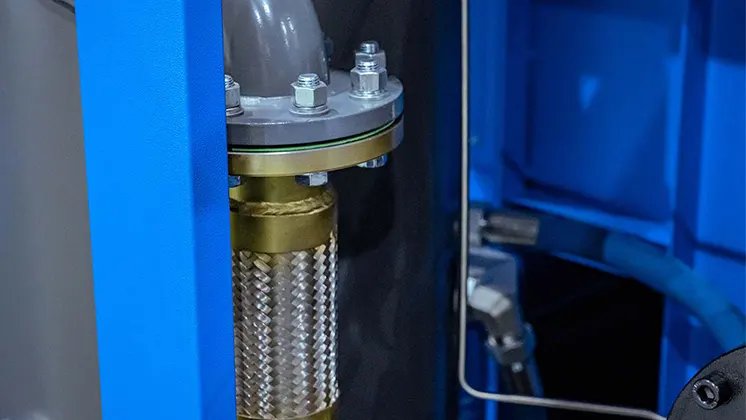

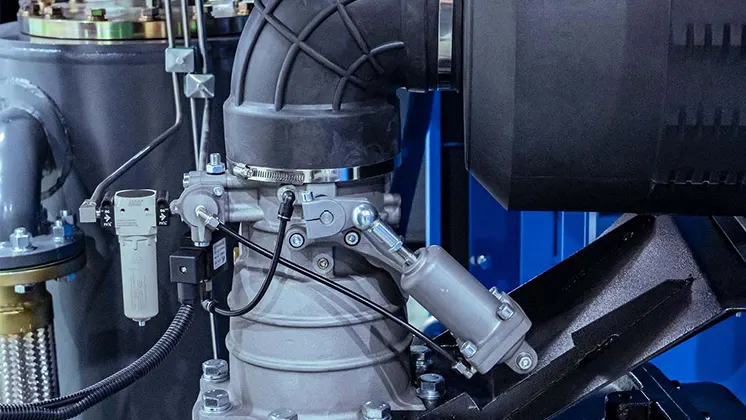

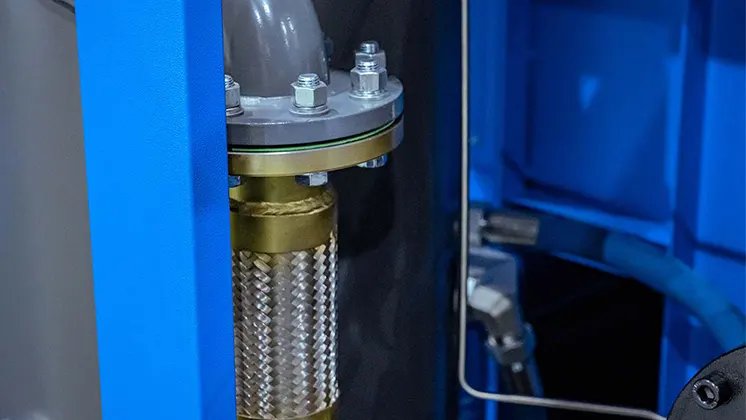

If the pressure demand is taken away the JX 10APMS is capable of exhausting at pressures of 0.8MPa, 1.0MPa, and 1.3MPa according to the numbers with exhaust volume in CFM of 1.1, 0.9, and 0.7 respectively. They are setting a noise level quality of not more than 63 dB(a), which is perfect or ideal since the equipment can come with a low noise emission environment. The compressor comes with a direct connection drive that guarantees the smooth running of the compressor besides the engine.

-1-696x1024.jpg)

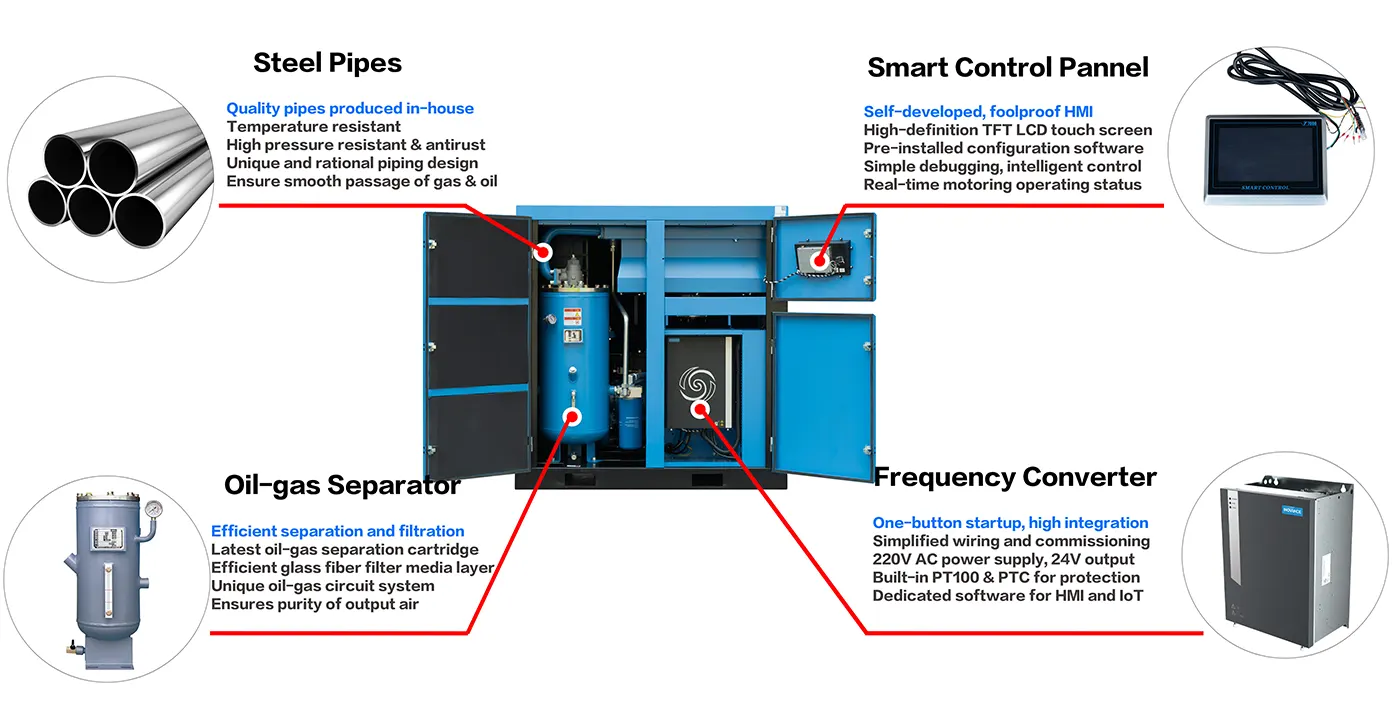

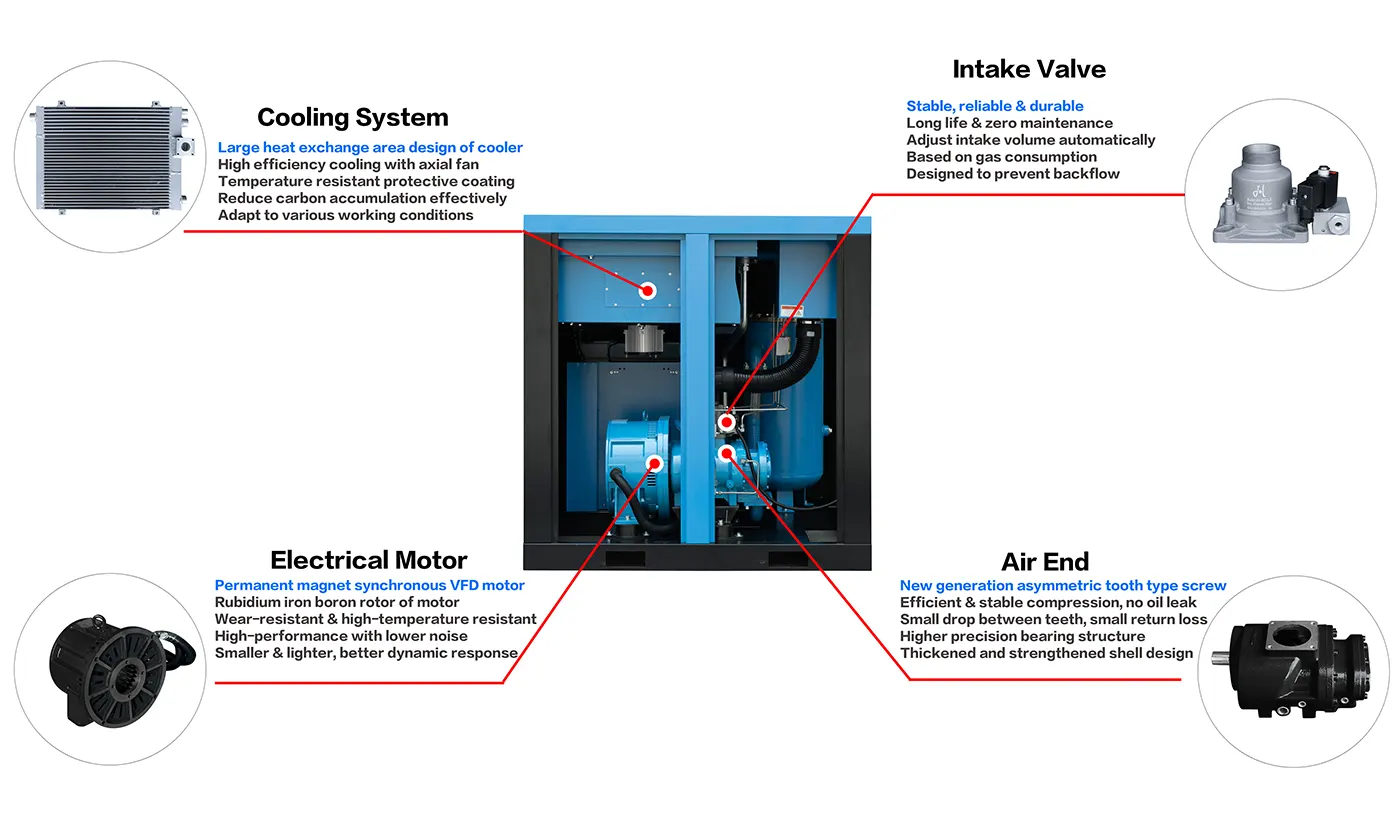

- Single Stage Compression: Functions either in one phase only, or delivers an appropriate air compression; make certain that the operation carries on continuously and the compressor is reliable.

- Variable Frequency Drive: To make it function according to the requirement of the clients, a variable frequency Startup mode is included.

- Air-Cooled System: This is slightly cooler for even more wearing and in various climate temperatures.

- Low Oil Content: However, there are still models that can go as far as burning out at 3ppm of exhaust oil and below and blowing out fresh air.

- Compact Design: It measures 800mm wide 600mm deep and 860mm height high and even though it is a small printer, it is small but efficient and can easily be placed in any space it will still offer the best services.

The world’s energy is getting tighter and tighter, the cost of electricity for enterprises is rising sharply, more efficient and energy-saving equipments can help enterprises to reduce the operation cost; with the enhancement of enterprises’ awareness of environmental protection, more environmentally friendly equipments are also needed; in developing countries, due to the rapid development of economy and industrialization, small and medium-sized enterprises are building a large number of factories, and the demand for various types and functions of air compressors is increasing; 10HP/7.5KW permanent magnet frequency conversion air compressors are developed to meet these background demands. The 10HP/7.5KW permanent magnet frequency conversion air compressor is a product developed based on such a background demand.

According to the needs of the site equipment, determine the required pressure and flow rate, consider the power, select the appropriate air compressor; compared with other brands, our production of VIBRANT brand air compressor, higher energy efficiency, cost-effective, good after-sales service, fast response in the event of equipment failure, is a good choice.

- Routine Maintenance: The other sector involves checking on the condition of the filters and the lubricants with the aim of ascertaining whether are still in their best state to perform their meant role of serving the compressor for a still enhanced time.

- Adequate Ventilation: Thus, do not bring the unit to work under high temperature conditions, the unit also needs proper ventilation.

- Electrical Supply Verification: Hence, find out if the connection could be an issue of the compressor, to prevent you from contaminating it.

- Monitoring Operating Conditions: Operating temperature and pressure also must be evaluated frequently to prevent a catastrophic event from happening.

- Workshops: Well suited where there are small to medium production plants that may need a supply of air for use in pneumatic tools and equipment.

- Automotive Repair: Most suitable for applications where industries regularly furnish compressed air to their structures and facilities.

- Light Industrial Use: A perfect answer to many spheres of life that need a stable and effective supply of air.

- Construction Sites: Make sure that construction tools and equipment have logistic transport at the construction point.

- DIY Projects: It should also be mentioned that this equipment is home-use appropriate, fulfills cross-terminal functions in the house, and may be all-rounded in all aspects.

| Item | Technical Parameter | |

| Unit Model | JX-10APMS | |

| Exhaust Pressure (MPa) | 0.8/1.0/1.3 | |

| Exhaust Volume (m3/min) | 1.1/0.9/0.7 | |

| Cooling Mode | Air-cooled | |

| Maximum Environmental Temperature | 46℃ | |

| Number of Compression Stages | Single-stage | |

| Exhaust Oil Content | ≤3 ppm | |

| Operating Noise dB(a) ±2 | ≤63 | |

| Outlet Pipe Diameter | G1/2 | |

| Drive mode | Direct Connection | |

| Amount of Lubricant (L) | 4 | |

| Lubricant Grade | 46# | |

| Power Supply | Tree-phase 380V/50Hz, can be customized | |

| Inspiratory State | Temperature (℃) | Ordinary Temperature |

| Pressure (MPa) | 0.1033 | |

| Relative Humidity | 60% | |

| Motor | Rated Power (HP/KW) | 10/7.5 |

| Voltage (V)/ Frequency (Hz) | 380/170 | |

| Speed (RPM) | 3400 | |

| Startup Mode | Variable Frequency Start | |

| Protection Grade | IP23,Can be customized | |

| Insulation Grade | F | |

| Usage Factor | 1.2 | |

| Overall Dimension L×W×H (mm) | 800*600*860 | |

| Unit Weight (Kg) | 112 | |

Media error: Format(s) not supported or source(s) not found

Download File: https://www.vibmac.com/wp-content/uploads/2024/09/new_JX_APMS_video_01.mp4?_=1

-

Pressure(MPa): 0.8/1.0/1.3

-

Exhaust Volume(m³/min): 1.1/0.9/0.7

-

Power(KW/HP): 7.5/10

-

Dimension(mm): 800*600*860

-

Noise dB(A): ≤63±2

-

Weigt(kg): 112

-

Pipe Diameter: G1/2

-

Startup Mode: Variable Frequency Start

-

Power Supply: Tree-phase 380V/50Hz , Can be customized

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 1.7~1.0

-

Power(KW/HP): 11/15

-

Dimension(mm): 1000*750*1070

-

Noise dB(A): ≤65±2

-

Weigt(kg): 195

-

Pipe Diameter: G3/4

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 11.2

-

Power(KW/HP): 90/125

VIEW MORE