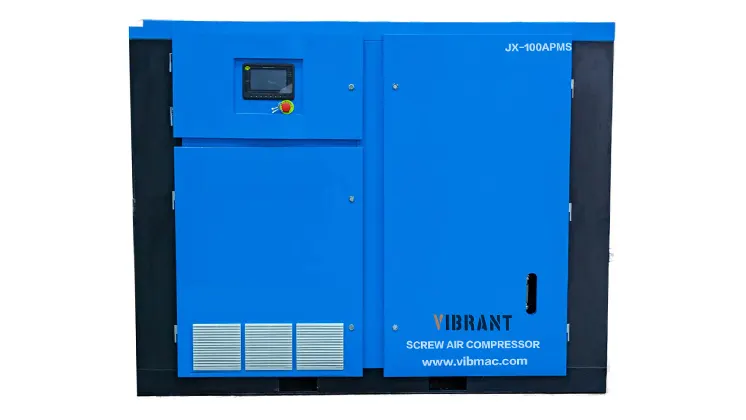

Best Single Stage Air Compressor (PM VSD)

It is here that we introduce to your attention the JX-100APMS Single Stage Air Compressor which is a member of the highest category of the market and developed for trouble-free operation in various fields. This air compressor, for instance, has an exhaust pressure of 0.8 MPa and a flow rate of 12.3 m³/min and offers high reliability in addition to a high output. Abroad type has an air-cooled structure in the overall design and can run in high-temperature environments with temperature peaks of up to 46 ℃ The deviated operational mode of the JX-100APMS is the variable frequency startup mode, branching from the conventional auto-change model.

- Pressure(MPa): 0.8

- Exhaust Volume(m³/min): 12.3

- Power(KW/HP): 75/100

- Dimension(mm): 1500*1230*1550

- Noise dB(A): ≤82±2

- Weigt(kg): 950

- Pipe Diameter: G2

- Startup Mode: Variable Frequency Start

- Power Supply: Tree-phase 380V/50Hz , Can be customized

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now

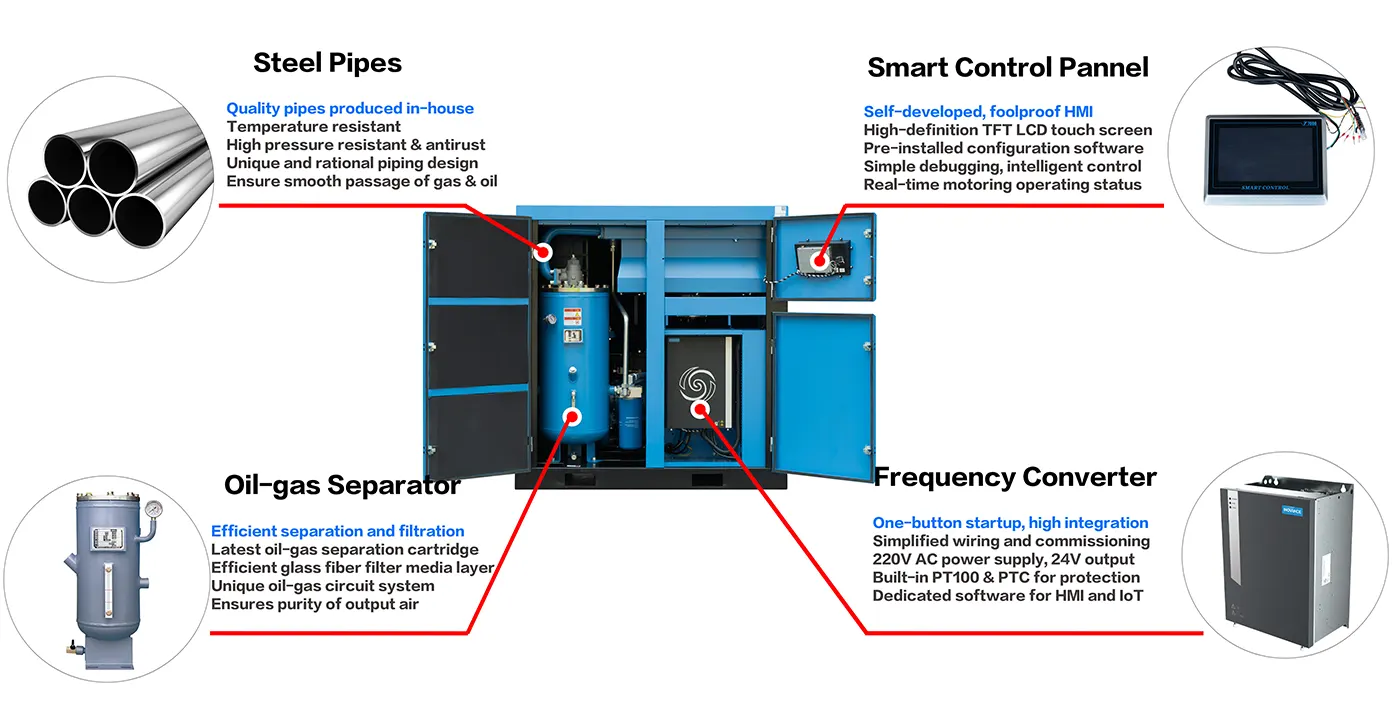

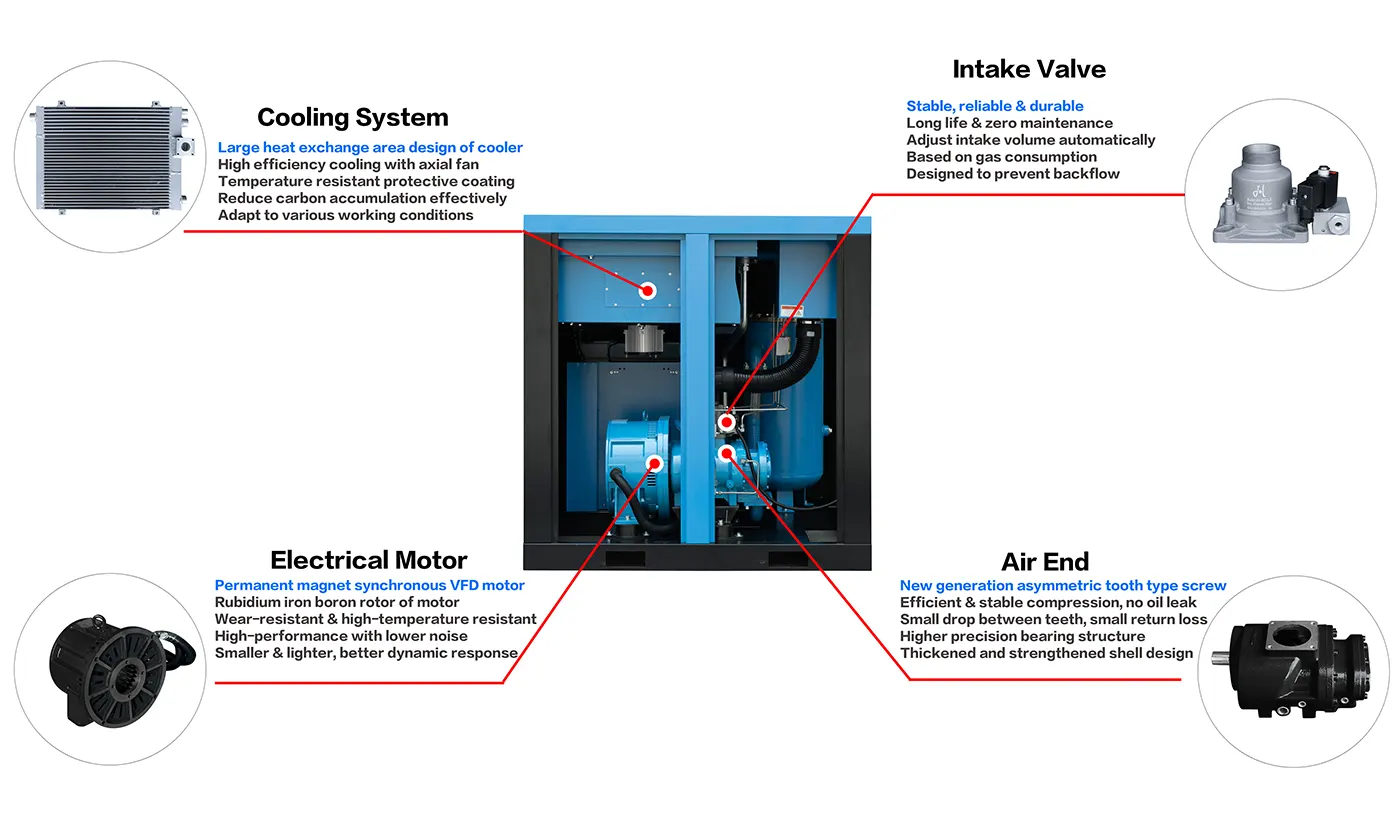

Our JX-100APMS-100HP/75KW model PM VSD screw air compressor produced adopts advanced permanent magnet frequency conversion(PM VSD) technology At present, JX-100APMS is a one-stage air compressor, which boasts a steady air supply rate in the maximum exhausted pressure of 0.8 MPa. It operates at marginally lower exhaust oil content of not less than 3 ppm allowing it to have better quality air emissions. The reciprocating compressor is of 100 HP (75 kW) and 3900 FPM rpm type. The physical dimensions of this standard-sized equipment are a length of 1500mm, width of 1230mm, height of 1550mm, and weight of 950kg, which certifies that it can fit into all manner of installation areas irrespective of the size, though very high performing.

-1-696x1024.jpg)

- High Exhaust Pressure: Thus for many pneumatic applications it can function smoothly at a pressure of 0.8 MPa.

- Generous Exhaust Volume: Can produce a flow rate of 12.3 m³/min sufficient to provide an appropriate flow rate to all the tools and equipment.

- Air-Cooled Design: This protects and retains a great performing, and durable part in several situations.

- Low Noise Operation: With a maximum operating sound pressure of ≤80 dB(a), it is suitable in areas of noise sensitivity.

- Robust Build Quality: Protection type being IP23 and insulation type being F.

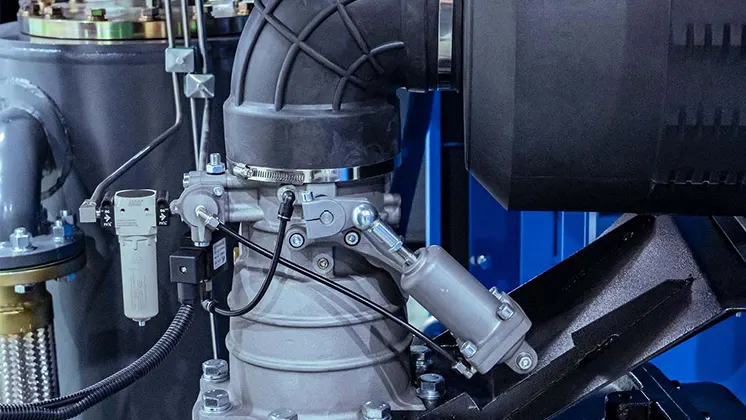

- Single-Stage Compression Mechanism: Improves the capacity of air compression while mitigating losses of energy within the procedure.

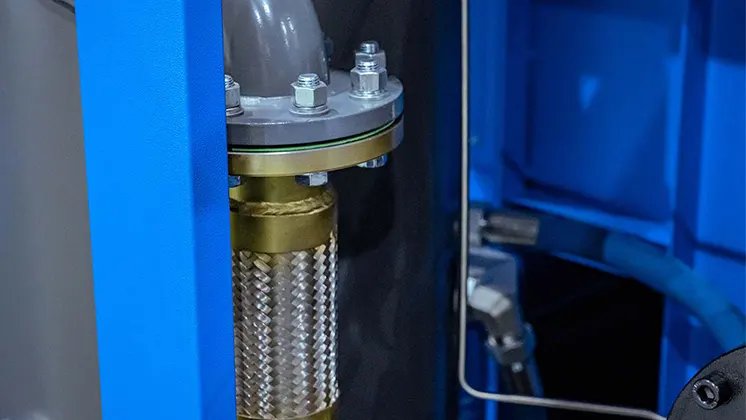

- Cooling System: The air cooling system is used to cool the compressor, thus it will be able to work at the right temperature.

- Lubrication System: Capable of holding 31ltrs of lubricant and employs 46# as its recommended grade for easy running of the Machine.

- Filters: A necessity to keep consumption of the oil in the exhaust emission as low as possible to spare the other internal components.

- Drive System: The coil is single and affords a united connection to efficient energy transmission from the motor to the compressor.

- Ensure Proper Ventilation: It is also important to see that there is a good flow of air round the compressor so that it does not over heat especially when in use.

- Regular Maintenance Checks: For the best results of the car, filters, belts and hoses should be checked as well as replaced sometime later.

- Verify Power Supply: Refer to electrical requirements to equate the loads to the compressor; otherwise, the compressor will be shorted.

- Monitor for Air Leaks: Some of them recommended that one should often check on the system so that they can be in a position to see that there is a leakage and which will not be wasting energy.

In order to solve the urgent needs of automobile manufacturing, textile, food processing and other industries for efficient, reliable and environmentally friendly compressed air systems, we have conducted in-depth market research and longtime communication with our loyal customers, and have analyzed the problems of the traditional fixed-speed air compressors (e.g., low energy-efficiency, high energy consumption, high noise, etc.), and the traditional compressors have been gradually failing to adapt to and satisfy the requirements of the modern industry, and we have combined with the most advanced PM VSD technology with the best materials to develop this new permanent magnet frequency conversion air compressor. During the research and development period, we pay special attention to the improvement of energy efficiency ratio, the reduction of operating costs, environmental protection, and intelligence.

We have a R&D team consisting of experienced engineers and technical experts, using computer-aided design and simulation software to design and simulate the structure and working principle of the air compressor and test it, manufacturing prototypes according to the design drawings, equipped with advanced testing equipment and laboratories, and carrying out comprehensive performance testing and optimization in the laboratory and in the actual application scenarios, with every step strictly in accordance with the international standards, to ensure that each product meets the high standards of industrial applications, and further adjust the product design in customer use. Through continuous technological innovation and strict quality control, our high-quality, high-performance air compressor products have been successfully applied in many industries.

The JX-100APMS-100HP/75KW PM variable frequency screw air compressor permanent magnet frequency conversion screw air compressor is a concentrated manifestation of VIBRANT’s technical strength after deeply understanding the high efficiency and energy-saving needs of industrial production, which not only significantly saves the user’s energy, reduces the operation and maintenance costs, but also improves the production efficiency and is friendly to the environment, making it a good helper for industrial factories.

- Industrial Manufacturing: Conductive to most manufacturing environments as a delivered air source for pneumatic instruments.

- Automotive Repair Shops: Recommended for charging air tools and equipment as those used in automobile-related activities.

- Construction Sites: Delivers clean and dry compressed air with plant efficiency for diverse tools and equipment in the plant.

- Food Processing and Packaging: Some of the uses are; Low oil content for consideration of food preparation processes and other food-related uses etc.

- General Workshops: Perfect for beginners and anyone who requires quality air for their projects within their homes or companies.

| Item | Technical Parameter | |

| Unit Model | JX-100APMS | |

| Exhaust Pressure (MPa) | 0.8 | |

| Exhaust Volume (m3/min) | 12.3 | |

| Cooling Mode | Air-cooled | |

| Maximum Environmental Temperature | 46℃ | |

| Number of Compression Stages | Single-stage | |

| Exhaust Oil Content | ≤3 ppm | |

| Operating Noise dB(a) ±2 | ≤80 | |

| Outlet Pipe Diameter | G2 | |

| Drive mode | Direct Connection | |

| Amount of Lubricant (L) | 31 | |

| Lubricant Grade | 46# | |

| Power Supply | Tree-phase 380V/50Hz, can be customized | |

| Inspiratory State | Temperature (℃) | Ordinary Temperature |

| Pressure (MPa) | 0.1033 | |

| Relative Humidity | 60% | |

| Motor | Rated Power (HP/KW) | 100/75 |

| Voltage (V)/ Frequency (Hz) | 380/150 | |

| Speed (RPM) | 3900 | |

| Startup Mode | Variable Frequency Start | |

| Protection Grade | IP23, can be customized | |

| Insulation Grade | F | |

| Usage Factor | 1.2 | |

| Overall Dimension L×W×H (mm) | 1500×1230×1550 | |

| Unit Weight (Kg) | 950 | |

Media error: Format(s) not supported or source(s) not found

Download File: https://www.vibmac.com/wp-content/uploads/2024/09/new_JX_APMS_video_03.mp4?_=1

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 3.4~2.5

-

Power(KW/HP): 22/30

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤72±2

-

Weigt(kg): 420

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 4.7~3.1

-

Power(KW/HP): 30/40

-

Dimension(mm): 1100*850*1110

-

Noise dB(A): ≤75±2

-

Weigt(kg): 450

-

Pipe Diameter: G1

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 6.4~4.7

-

Power(KW/HP): 37/50

-

Dimension(mm): 1200*1000*1350

-

Noise dB(A): ≤77±2

-

Weigt(kg): 600

-

Pipe Diameter: G1 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 9.4~6.2

-

Power(KW/HP): 55/75

-

Dimension(mm): 1500*1230*1550

-

Noise dB(A): ≤80±2

-

Weigt(kg): 850

-

Pipe Diameter: G2 1/2

-

Startup Mode: Frequency Conversion Start

-

Power Supply: 380V/50HZ, available for customization(110V~480V,50HZ/60HZ)

VIEW MORE

-

Pressure(MPa): 1.6

-

FAD (m³/min): 9.0

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.8~1.3

-

Exhaust Volume(m³/min): 12.2~9.1

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 0.7~1.3

-

Exhaust Volume(m³/min): 12.4~9.1

-

Power(KW/HP): 75/100

VIEW MORE

-

Pressure(MPa): 1.55

-

FAD (m³/min): 0.6

-

Power(KW/HP): 7.5/ 10

VIEW MORE