What is a 15 Horsepower Air Compressor?

A 15 HP air compressor is an example of an industrial-grade machine that achieves high volumes and pressures of compressed air. It is built for intensive applications and is typically found in:

• Automobile shops

• Construction sites

• Manufacturing Plants

• Sandblasting Operations

• Painting Booths

• Pneumatic Tool Systems

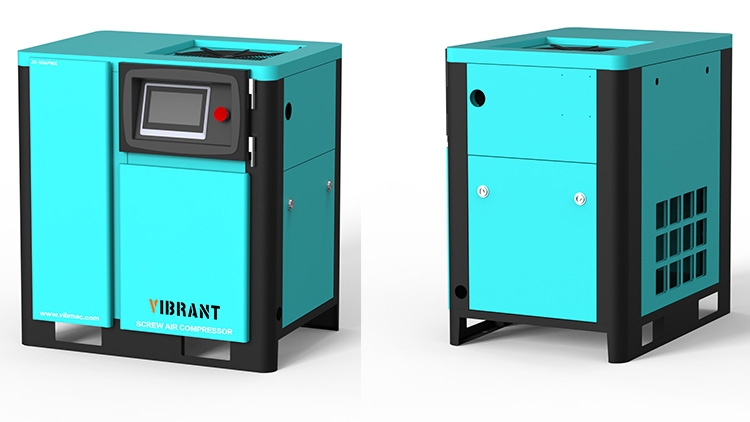

When it comes to the best 15 horsepower compressor for precision and efficiency, the PM VSD Screw Air Compressor takes the lead. Unlike other models, the PM VSD has a blend of permanent magnet motors with variable speed drives (VSD), allowing this machine to achieve optimal performance and precise control, resulting in energy efficiency and reliability.

Main Advantages of JXPMX 15 HP Air Compressor

Offering optimal features for strenuous industrial applications, the JXPMX Series of 15 HP PM VSD air compressors has the following advantages:

Stable and Reliable Operation

• Fast startup

• Smooth control

• Non-overshoot steady performance

• Exceptional in high-load and damped systems

High Energy Efficiency

• Permanent magnet motor drives are 3 5% more efficiently energised than other types of motors.

• Operates efficiently even at small rotational speeds.

• Airflow is matched to requirements due to a change in speed.

Vital to starting compressors is the absence of impact.

• The soft starter reduces the front current to 1.2 times the rated current, enabling Non-Impact Starting.

Less Electrical Impact

• Reduced electromechanical stress on the equipment, enabling prolonged equipment lifespan.

Leakage

• Avoidance of oil leakage also ensures the clean operation and avoids carryover from one compartment to another.

No Noise & Low Vibration

• Enhanced engineering precision leads to reduced internal noise and long-term maintenance expenses.

High-performance surveillance system

• More than 20 parameters of the system can be captured for further analysis.

Preventive shutdown alerts

Reduce idle time and optimize workload for the correct system requirement.

Micro-Oil Lubrication

• Features extremely accurate mechanisms that deliver compressed air, enabling sensitive use in medical and textile industries.

Uses of the PM VSD 15 HP Air Compressor

Because of its adaptability and dependability, the 15 horsepower air compressor is ideally suited for a wide variety of industries. It is especially helpful in:

Industrial Manufacturing:

Used in operating pneumatic machinery, assembly lines, CNC machines, and other industrial machines; heavy-duty tools can also be powered.

Medical Industry:

Clean, compressed air is vital for the functions of medical devices and tools in clinics, hospitals, and other healthcare facilities.

Textile Industry:

Required for providing airflow throughout the spinning, weaving, dyeing, and finishing processes.

Automotive & Motor Industry:

Ideal for spray painting, inflation of tires, impact wrench usage, and robotic assembly operations.

Simplicity is the Ultimate Sophistication

One of the standout features of the PM VSD Screw Air Compressor is its low maintenance design. With fewer consumable parts and easy access panels, service is:

• Swift

• Economical

• Uncomplicated

Its design makes the device perfect for long-term use. It can withstand long operational periods, making it a good purchase for businesses that face supply challenges and are trying to lower operational expenses.

Integrated Protection Features

Safety is our top concern. This 15 HP air compressor comes with:

• PTC temperature monitoring

• Intelligent controllers for over temperature conditions

• Over shut off and protection systems

These features prevent overheating, safeguard the motors from damage, and provide the required safety for clean operation in your entire system.

Why Choose VIBRANT as Your 15 HP Compressor Supplier?

VIBRANT is a well-known name in high-efficiency air compressor solutions. We stand as a manufacturer and supplier of:

• A comprehensive listing of 15hp industrial air compressors.

• The most economical and cheapest energy costing systems.

• High-quality performance WEG motors from China at the lowest price.

• Unmatched support quality endorsed by experts.

We aim to be the world’s best integrator of compressed air solutions in the world- delivering unrivaled price- performance.

Where to buy A 15 HP Air Compressor?

If you are looking for a reliable 15 horsepower air compressor with great performance with efficiency, check the VIBRANT range of compressors and accessories- your trusted name in air compression solutions.

Core Metrics: Understanding Critical Specifications

Prior to buying a 15-horsepower compressor, knowing its technical specifications is critical. You should pay attention to the following key features:

CFM (Cubic Feet per Minute)

• Describes the volume of air delivered by the compressor.

• A 15 HP rotary screw compressor usually delivers between 50 to 70 CFM at 125 PSI.

• Higher CFM is preferred for tools needing constant air flow, such as grinders or paint sprayers.

PSI (Pounds per Square Inch)

• Indications of the pressure within the compressed air.

• Almost all 15 HP units will run around 125-175 PSI, which is great for industrial-grade tools.

Tank Size

• Determines how long you can work without waiting for the motor to turn on.

• Typical choices include: 60-gallon, 80-gallon, and 120-gallon tanks.

Voltage Requirements

• 15 HP air compressors are typically 3-phase and operate at 230V or 460V.

• Some piston units might allow single-phase configurations for non-industrial powered workshops.

Duty Cycle

• A 15 HP air compressor should provide a 100% duty cycle, which enables continuous use without overheating.

What to Look for in a 15 HP Air Compressor?

Before the buying decision, consider the following:

• Compatibility with tools in terms of CFM & PSI.

• Runtime requirements regarding tank capacity.

• Noise level (dBA)

• Type of cooling system (air-cooled or water-cooled)

• Voltage and phase

• Portable or stationary installation

• Moisture removal via built-in dryer or filter.

Maintenance Guidelines for 15 HP Air Compressors

To ensure your device operates at maximum efficiency, see the following maintenance objectives:

- Inspect the oil level every week (for oil-lubricated types).

- Remove moisture from the tank on a daily basis.

- Check air filters on a monthly basis.

- Change belts and seals on an annual basis.

- Have an expert examine your device once every year.

Conclusion

The 15 horsepower air compressor is designed for compressors that need reliability, efficiency, and power. It employs air to make the required compressive power. You can have an oil-free quiet air compressor, a rugged rotary screw system, or a standard piston model, all depending on what suits your business needs. Visit our site if you are looking for industrial air compressors, or give us a call to guide you through your inquiries.